Metallurgical Abstracts on Light Metals and Alloys vol.57

Upgrading recycling of Al–7wt%Si alloys using electromagnetic force in directional solidification

Takuya Tamura and Mingjun Li*

* National Institute of Advanced Industrial Science and Technology (AIST), Innovative Functional Materials Research Institute

[Published in Journal of Alloys and Compounds, (2024), 173528]

https://doi.org/10.1016/j.jallcom.2024.173528

E-mail: takuya-tamura[at]aist.go.jp

Key Words: Al–7wt%Si alloy, Electromagnetic force, Continuous casting, Solute redistribution, Fluid flow, Recycling

The primary recycling of post-consumer Al in industries currently proceeds mainly in a cascade manner, which is not sustainable when considering the Al cycle trends in the coming decades. Herein, we develop a novel process to separate primary Al from the crystallizing liquid when a constant electromagnetic force (EMF) is applied. Using this technique, we successfully upgraded Al–7wt%Si (hereafter, unless specified otherwise) alloy to approximately Al–3.6%Si in directional solidification. The separation mechanism was discussed in terms of the electrical properties of the respective phases during solidification. Fluid flow simulation results were applied to elucidate the separation behavior in the alloy. The upper and lower limits to separate the crystallizing alloy into an Al-rich and Si-rich areas were determined when the controlling factors were clarified, which made it possible to scale up the present laboratory-based setup to an industrial level. Moreover, the energy consumption of the process was slightly higher than that required for remelting only. This energy-saving and eco-friendly process can provide a breakthrough to overcome the “dead metal” crisis and thus realize sustainability by upgrading recycling of post-consumer hypoeutectic Al–Si casting alloys.

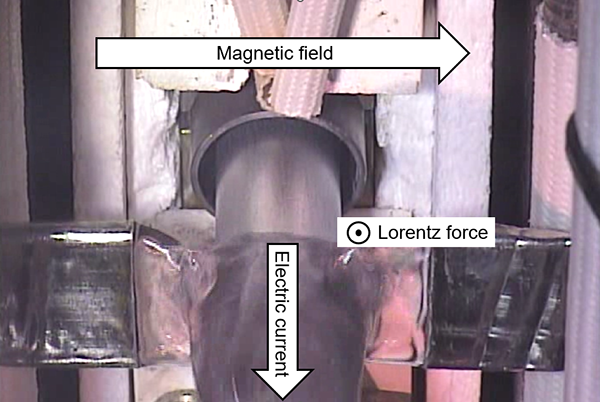

Photograph of the continuous casting using electromagnetic force for Al–7wt%Si alloys.