Metallurgical Abstracts on Light Metals and Alloys vol.57

Effect of grain size on slip system activity and room temperature strain aging in commercially pure titanium rolled sheets

Takuma Hirooka*, Hiromoto Kitahara** and Shinji Ando**

* Graduate School of Science and Technology, Kumamoto University

** Magnesium Research Center, Kumamoto University

[Published in Journal of The Japan Institute of Light Metals, Vol. 74 (2024), pp. 421-426]

https://www.jstage.jst.go.jp/article/jilm/74/9/74_740902/_article/-char/en

E-mail: kitahara[at]msre.kumamoto-u.ac.jp

Key Words: prismatic slip, pyramidal slip, basal slips, ductility, grain boundary sliding

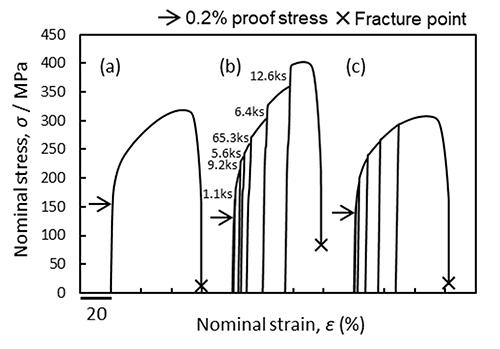

Commercially pure titanium rolled sheets with different grain sizes of 20, 50 and 80 µm were applied to tensile tests to investigate the effects of grain size on the relationship between mechanical properties and activities of slip systems. While the ductility was independent of grain size, the activity of first order pyramidal slips and second order pyramidal slips decreased with decreasing grain size. In addition, grain boundary sliding was found to contribute to ductility when the grain size was small. Prismatic slips were activated in all of the specimens when yielded. Activity of pyramidal slips increased with increasing strain and decreased with decreasing grain size. Tensile tests were interrupted and slip lines were observed after the unloading in this study. Yield stress increment was observed when reloaded in interrupt tensile tests, but not in immediate reloading tensile tests. We found room temperature strain aging in pure titanium sheets. Yield stress increment increased with increasing strain.

Stress-strain curves of rolled pure titanium sheets in (a) conventional tensile test, (b) interrupted tensile test with time interval and (c) interrupted tensile test without interval time.