Metallurgical Abstracts on Light Metals and Alloys vol.57

Fabrication of Al-(Al3Ti+Diamond) Functionally Graded Grinding Wheels by the Centrifugal Sintered-Casting Method

Yoshimi Watanabe1, Yasuhiko Izawa1, Motoko Yamada1, Hisashi Sato1, Takahiro Kunimine2 and Hideaki Tsuge3

1 Nagoya Institute of Technology

2 Kanazawa University

3 Gifu Prefectural Industrial Technology Center

[Published in Journal of the Japan Society for Composite Materials, 49, No. 4, 115-124 (2023)]

https://doi.org/10.6089/jscm.49.115

E-mail: yoshimi[at]nitech.ac.jp

Key Words: Functionally graded materials, Centrifugal force, Heterogeneous nucleation, Drilling, Carbon fiber-reinforced plastic (CFRP)

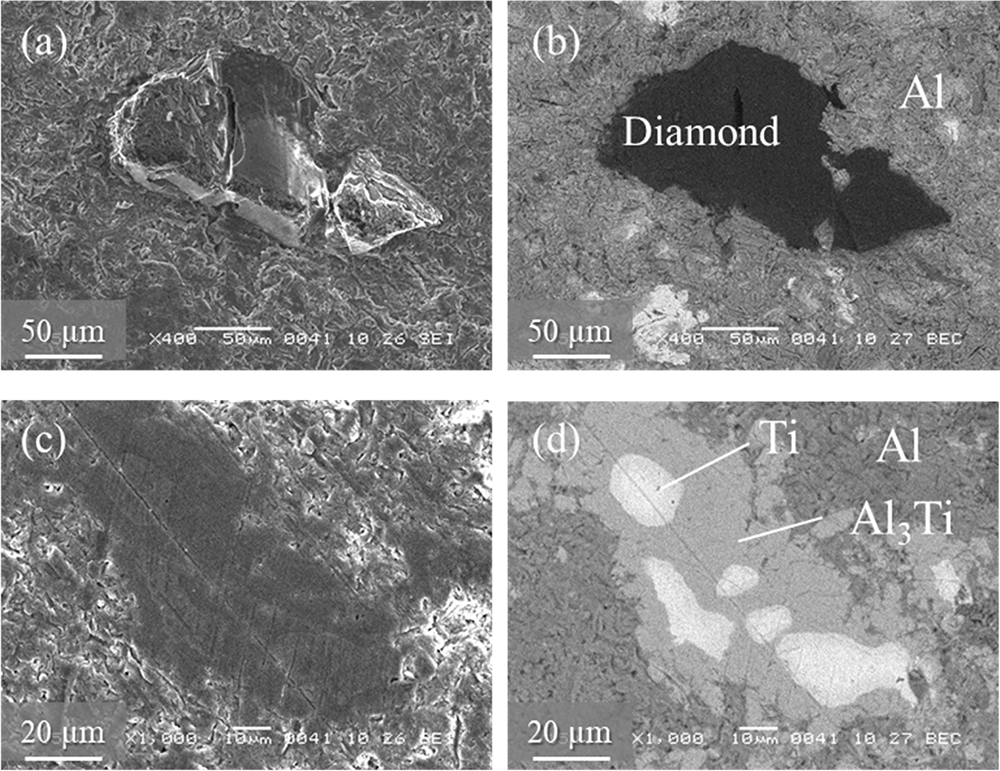

In this study, an Al-(Al3Ti + Diamond) functionally graded grinding wheel, a kind of functionally graded material, was fabricated by the centrifugal sintered-casting method, which combines centrifugal sintering and centrifugal casting. A mixture of diamond grains, Al particles, and Ti particles was sintered under the centrifugal force to fabricate a ring-shaped preform. During this process, the exothermic reaction of 3Al + Ti → Al3Ti promoted sintering. The molten Al matrix metal was subsequently poured into the fabricated preform under a centrifugal force (centrifugal casting) to obtain a functionally graded grinding wheel. The drilling performance of the fabricated functionally graded grinding wheel for carbon fiber-reinforced plastic (CFRP) laminates was also investigated using a dual-axis grinding wheel system. Our results show that the Al3Ti phase acts as a heterogenous nucleation site during centrifugal casting, resulting in a refined and uniform microstructure with enhanced mechanical properties.

SEM secondary electron images ((a) and (c)) and backscattered electron images ((b) and (d)) of the 25Ti-1h functionally graded grinding wheel sample focused on diamond ((a) and (b)) and Al3Ti ((c) and (d)).