Metallurgical Abstracts on Light Metals and Alloys vol.57

Mg Alloy Rod Strengthened by Combined Processes of Deformation-Restricted Forging and Extrusion

H. Miura*, Y. Oba*, C. Watanabe** and T. Benjanarasuth***

* Department of Mechanical Engineering, Toyohashi University of Technology, Toyohashi 441-8580, Japan

** Faculty of Mechanical Science and Engineering, Kanazawa University, Kanazawa 920-1192, Japan

*** School of Engineering, King Mongkut’s Institute of Technology Ladkrabang, Bangkok 10520, Thailand

[Published in Mater. Trans., Vol. 65 (2024) pp. 93-96]

https://doi.org/10.2320/matertrans.MT-M2023135

E-mail: Miura[at]me.tut.ac.jp

Key Words: magnesium, rod, twin, mechanical property, microstructure, forging, DRF

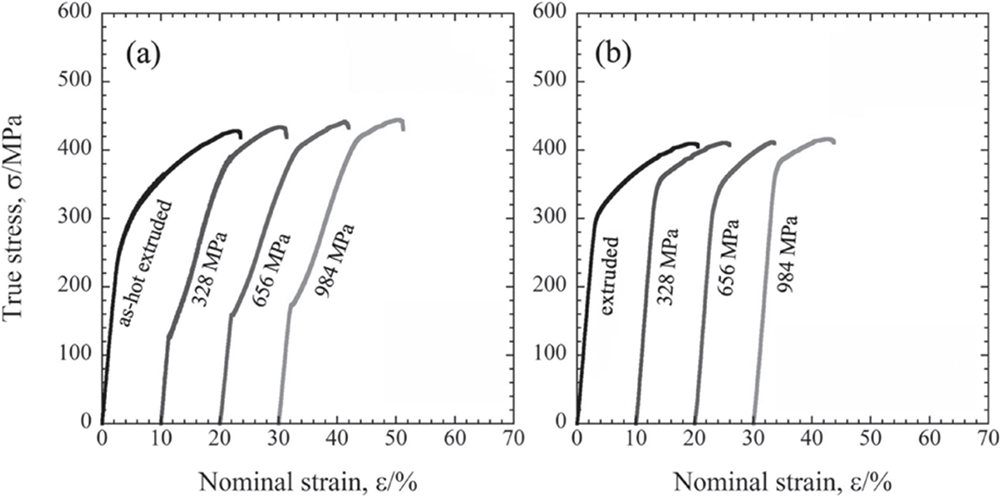

A new method for strengthening Mg alloy rod is proposed. AZ80Mg alloy rods were forged along the longitudinal axis (LA) at extremely high pressures beyond fracture stress under a condition where plastic deformation was eliminated in a die, i.e., deformation-restricted forging (DRFing), followed by cold extrusion. The developed coarse twins obtained by DRFing disappeared after extrusion, in which finer ones replaced the initial twins. Although the ultimate tensile strength (UTS) and hardness were gradually raised with DRFing stress, the yield strength (YS) was lowered by sharp basal texture evolution on the plane normal to the LA and tensile axis. However, the extrusion after DRFing drastically changed the texture to (0001) || LA, causing a large increase in YS. Consequently, a superior balance of mechanical properties: YS of 376 MPa, UTS of 417 MPa, and ductility of 10%, could be achieved after the combined processes of DRFing and extrusion.

Stress - strain curves attained by tensile tests along the longitudinal direction of the processed AZ80Mg alloy rods; (a) as-DRFed rods and (b) DRFed rods followed by extrusion. For comparison, the flow curves of the as-hot extruded rod and it subjected to cold extrusion are also shown.