Metallurgical Abstracts on Light Metals and Alloys vol.57

Tensile Deformation Behaviors of Pure Ti with Different Grain Sizes under Wide-Range of Strain Rate

Misaki Deguchi*, Shigeto Yamasaki**, Masatoshi Mitsuhara***, Hideharu Nakashima***, Genki Tsukamoto**** and Tomonori Kunieda****

* Interdisciplinary Graduate School of Engineering Sciences, Kyushu University, Kasuga 816-8580, Japan

** Department of Materials, Kyushu University, Fukuoka 816-0395, Japan

*** Department of Materials Science and Engineering, Kyushu University, Fukuoka 816-8580, Japan

**** Steel Research Laboratories, Nippon Steel Corporation, 20-1 Shintomi, Futtsu, Chiba 293-0011, Japan

[Published in Materials, Vol. 16 (2023), 529]

https://doi.org/10.3390/ma16020529

E-mail: nakashima.hideharu.792[at]m.kyushu-u.ac.jp

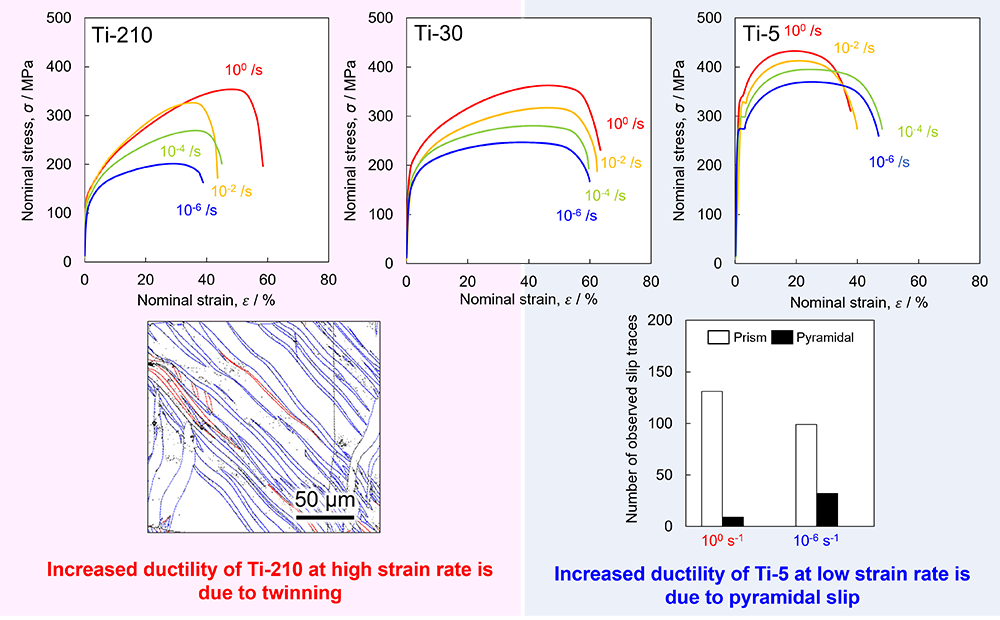

Key Words: CP-titanium, strain rates dependence, mechanical properties, twin, grain size, work hardening rate

In this study, pure titanium equivalent to Grade 1 was subjected to tensile tests at strain rates ranging from 10-6 to 100 s-1 to investigate the relationship between its mechanical properties and its twinning and slip. Deformation properties and microstructures of samples having average grain sizes of 210 µm (Ti-210), 30 µm (Ti-30), and 5 µm (Ti-5) were evaluated. With increasing strain rates, the 0.2% proof stress and ultimate tensile strength increased for all samples; the fracture strain increased for Ti-210, decreased for Ti-5, and changed negligibly for Ti-30. Comparing high (100 s-1) and low (10-6 s-1) strain rates, twinning occurred more frequently in Ti-30 and Ti-210 at high strain rates, but the frequency did not change in Ti-5. The frequency of 1st order pyramidal slip tended to be higher in Ti-30 and Ti-5 at low strain rates. The higher ductility exhibited by Ti-210 at high strain rates was attributed to the high frequency of twinning. In contrast, the higher ductility of Ti-5 at low strain rates was attributed to the activity of the 1st order pyramidal slip.

Deformation rate dependence of mechanical properties in CP-Ti; twinning frequency and dislocation slip mode depend on deformation rate and grain size.