Metallurgical Abstracts on Light Metals and Alloys vol.57

Optimization of Pore Formation Process of Lotus Aluminum by Phase Field Simulation

Kei Takahashi*, Kazuki Yamaguchi*,Yasushi Sasajima* and Teruyuki Ikeada*

* Institute of Quantum Beam Science, Graduate school of Science and Engineering, Ibaraki University, Hitachi 316-8511, Japan

[Published in ECS Advances, 2 (2023) 032001]

https://doi.org/10.1149/2754-2734/acee15

E-mail: yasushi.sasajima.mat [at] vc.ibaraki.ac.jp

Key Words: Lotus metal, Pore growth process, Directional solidification, Multi phase field method, PIⅮ control

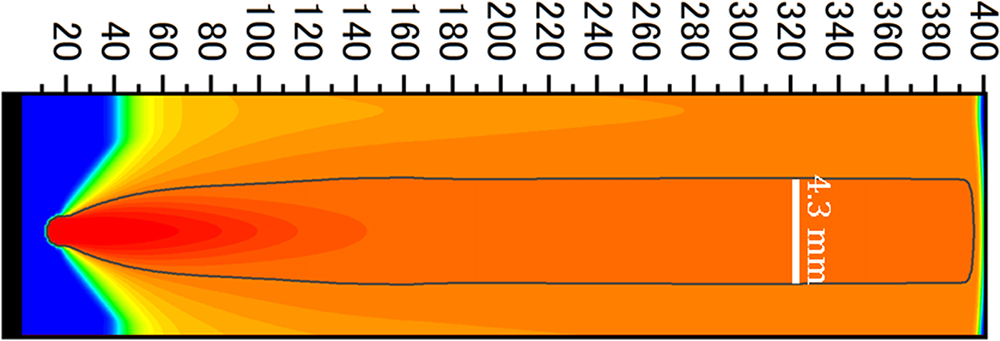

We have used multi-phase field simulation to mimic the actual process of lotus aluminum production, i.e., unidirectional solidification of aluminum in a hydrogen atmosphere. We used PD control and PID control, conventional methods of feedback control, to control the pore width precisely in the simulation. The pore width was shown to decrease slowly in PID control due to the slow feedback of I-control, and PD control was shown to produce stable long pores, although the pore width became larger than the target pore width. The initial hydrogen concentration in the liquid, which was controlled by atmospheric hydrogen pressure, had a significant effect on the pore growth; the higher the hydrogen concentration, the thicker the pore width and vice versa. It was also clarified that the pore width and the elongation length of the pore took various values depending on the combination of PD parameters even if the same target value was set.

Phase field of pore with the parameters optimized for the target value of 2.0 mm.