Metallurgical Abstracts on Light Metals and Alloys vol.57

Effects of Cooling Conditions Immediately after Solution Treatment on Microstructures and Mechanical Properties of JIS AC4CH Aluminum Casting Alloy

Naohiro Saruwatari*, Sumiya Koike**, Eiji Sekiya*** and Yoshihiro Nakayama*

* Graduate Faculty of Interdisciplinary Research, University of Yamanashi, Kofu 400-8511, Japan

** Integrated Graduate School of Medicine, Engineering, and Agricultural Sciences, University of Yamanashi, Kofu 400-8511, Japan (Present address: KeyTechnology Co., Ltd., Sawa-gun, Gunma 370-1122, Japan)

*** MARUSHIN-HEAT TREATMENT Co., Ltd., Kai 400-0116, Japan

[Published in Materials Transactions, Vol. 64 (2023), pp. 2575-2583]

https://www.jstage.jst.go.jp/article/matertrans/64/11/64_MT-F2023001/_article/-char/en

E-mail: nakayama[at]yamanashi.ac.jp

Key Words: JIS AC4CH alloy, solution treatment, cooling rate, temperature range, microstructure, mechanical property

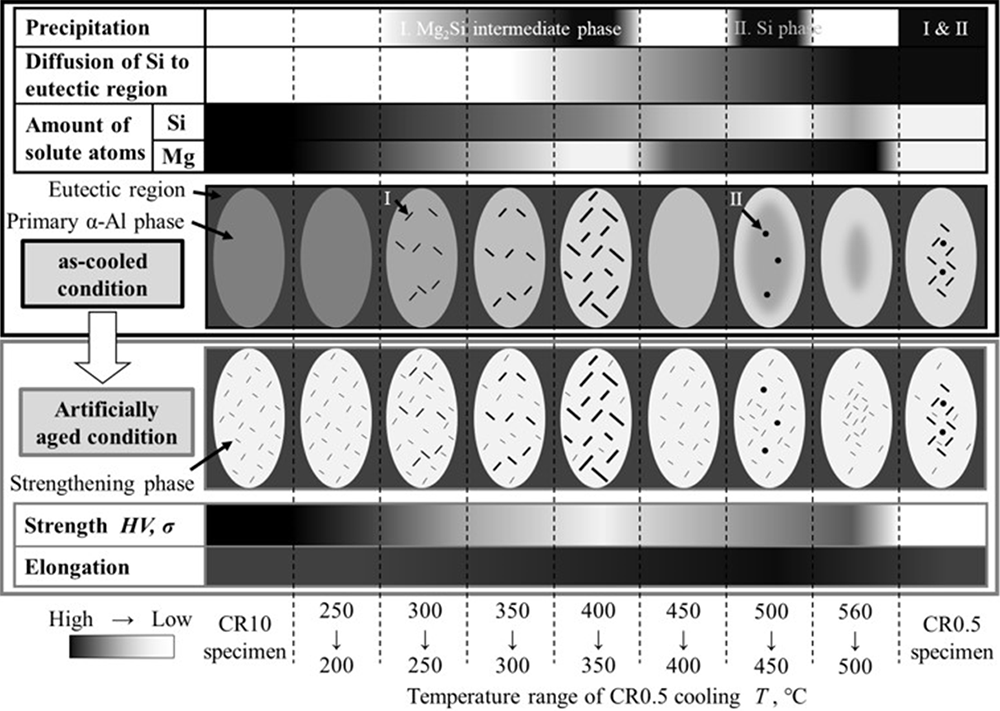

The objective of this study was to optimize the cooling conditions following the solution treatment of JIS AC4CH aluminum casting alloy. The effects of cooling at a rate of 0.5°C/s on the microstructure and mechanical properties were investigated. The temperature range and cooling rate were simultaneously adjusted using a high-frequency induction heating apparatus and air cooling. Specifically, a cooling rate of 10°C/s (CR10) was employed as the baseline, with a rate of 0.5°C/s (CR0.5) applied to a portion of the temperature range. Scanning electron microscopy (SEM) observations of the specimens post-cooling revealed the formation of rod-like precipitates in specimens cooled at CR0.5 within the range of 400–250°C. In specimens cooled at CR0.5 from 500 to 450°C, granular or rod-shaped precipitates with a small aspect ratio were observed. Scanning transmission electron microscopy with energy dispersive X-ray spectroscopy (STEM-EDS) identified the former as the Mg2Si intermediate phase and the latter as the primary Si. An electron probe micro analyzer (EPMA) measured the Mg and Si concentrations in the primary α-Al phase. For the temperature range of CR0.5 cooling above 350°C, the Si concentration significantly decreased as the temperature range of CR0.5 cooling increased. This decrease in Si concentration could be attributed to the diffusion of Si atoms to the eutectic region, considering the Si concentration distribution and diffusion distance in the primary α-Al phase. The 0.2% proof stress and tensile strength values after artificial aging of a specimen cooled at CR0.5 from 400 to 350°C, where a coarse Mg2Si intermediate phase precipitated during cooling, were approximately 10% lower than those of a specimen cooled at CR10 over the entire temperature range.

Summary of effects of CR0.5 cooling temperature range on microstructures and mechanical properties.