Metallurgical Abstracts on Light Metals and Alloys vol.57

Effect of Short-Time Heating after ECAP Processing on Mechanical Properties of 6061 Aluminum Alloy

Naohiro Saruwatari*, Hayate Kagami** and Yoshihiro Nakayama*

* Graduate Faculty of Interdisciplinary Research, University of Yamanashi, Kofu 400-8511, Japan

** Integrated Graduate School of Medicine, Engineering, and Agricultural Sciences, University of Yamanashi, Kofu 400-8511, Japan

[Published in Materials Transactions, Vol. 64 (2023), pp. 429-435]

https://www.jstage.jst.go.jp/article/matertrans/64/2/64_MT-LA2022028/_article/-char/en

E-mail: nakayama[at]yamanashi.ac.jp

Key Words: 6061 aluminum alloy, ECAP processing, aging, mechanical properties, microstructures

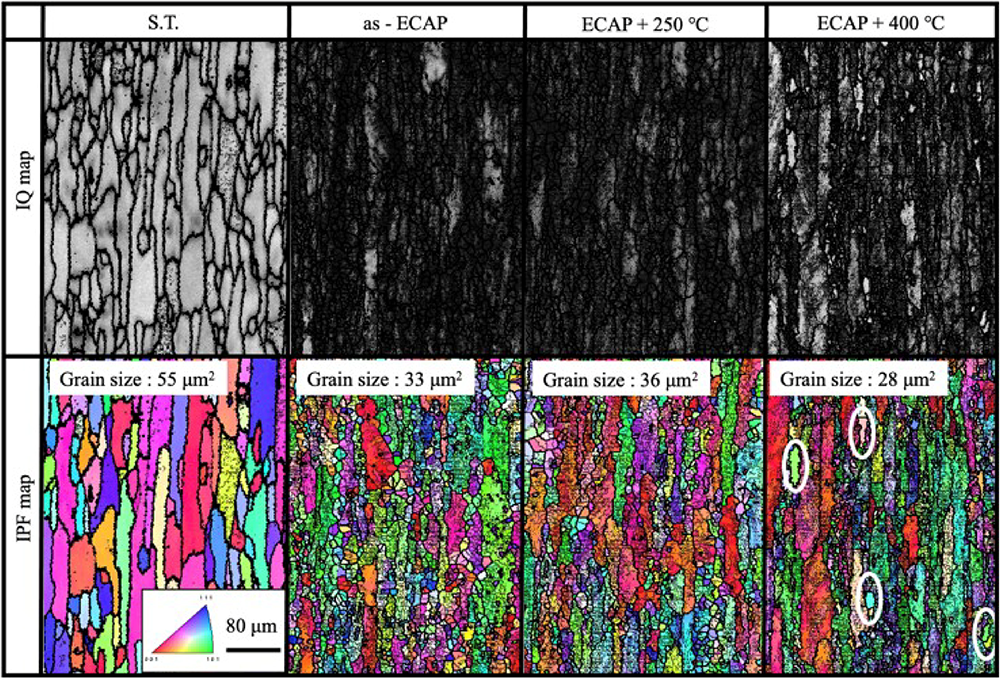

This study aimed to enhance the strength and ductility of Al-Mg-Si alloys through the combination of severe plastic deformation and heat treatment. A 6061 aluminum alloy, subjected to equal-channel angular pressing (ECAP) following solution treatment, was heated from 100°C to 400°C for 10 seconds. Electron backscatter diffraction analysis revealed that the fine grains produced via ECAP processing remained intact after a brief heating duration of 10 seconds at 400°C. Hardness test results indicated that the alloy begins to recover after short-term heating at approximately 200°C, with the strengthening phase precipitating at around 250°C. In contrast, artificial aging without short-term heating post-ECAP processing resulted in decreased alloy strength, likely due to recovery effects (reduction in dislocation density) during artificial aging. The 0.2% proof stress and ultimate tensile strength of specimens heated briefly at 200°C post-ECAP processing increased by 18 and 15 MPa, respectively, due to subsequent artificial aging. It is hypothesized that hardening from precipitation strengthening was induced by artificial aging, while dislocation density reduction was attributed to short-term heating. Specimens heated briefly at 300°C post-ECAP exhibited a significant decrease in strength after artificial aging. Although recovery occurred post-ECAP processing followed by short-term heating, the simultaneous precipitation state contributed to the alloy’s strength and ductility during subsequent artificial aging.

IQ and IPF maps for S.T., as-ECAP, and specimens subjected to short-time heating at 250°C and 400°C after ECAP processing (ECAP+250°C and ECAP +400°C, respectively).