Metallurgical Abstracts on Light Metals and Alloys vol.57

Effects of post-welded hot rolling on the properties of explosively welded Mg alloy/Al alloy cladding plates

Mami Mihara-Narita*, Mingzhe Bian**, Hisashi Sato*, Yoshimi Watanabe* and Yasumasa Chino**

* Department of Physical Science and Engineering, Nagoya Institute of Technology

** National Institute of Advanced Industrial Science and Technology (AIST)

[Published in Proceedings of IIW 2024, (2024), FP278]

E-mail: narita.mami[at]nitech.ac.jp

Key Words: explosive welding, hot rolling, magnesium alloy, aluminum alloy, interlayer

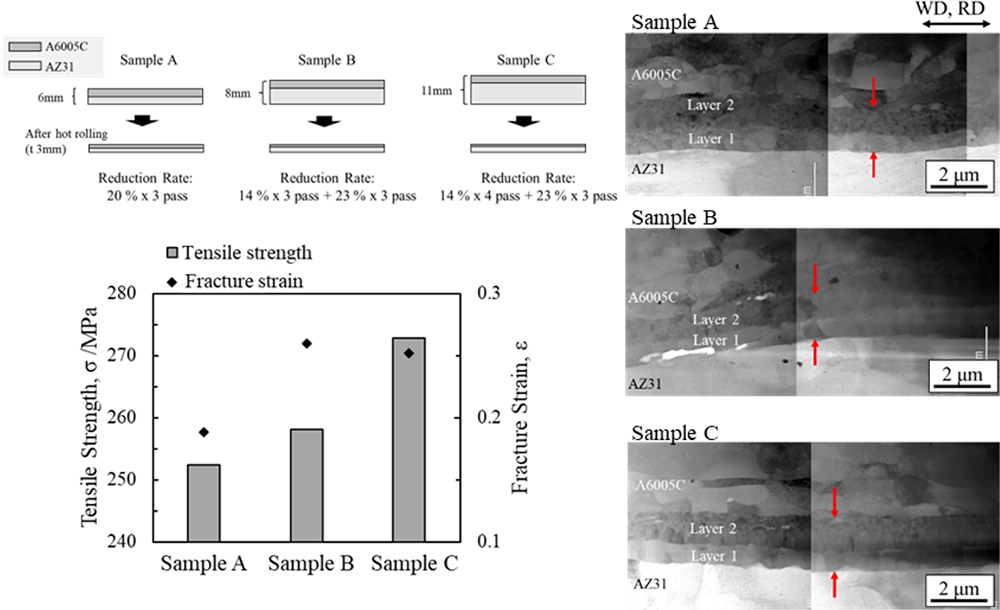

The effects of hot rolling on the interfacial microstructure and mechanical properties of explosively welded Mg alloy/ Al alloy cladding plates with different thickness of Mg alloy were investigated. Explosively welded cladding plates showed wavy interface at the bonding interface. After hot rolling, the interface became flat and the voids at the interface disappeared. The presence of the interlayer was confirmed at the bonding interface in all samples. While the interlayer before rolling was single layer of a magnesium-rich γ-Mg17Al12 phase, after rolling it became double layer composed of γ- Mg17Al12 phase and aluminum-rich β-Al3Mg2 phase. Tensile strength increased as the initial thickness of the Mg alloy increased, and ductility was also improved. It was found that hot rolling was possible when both the roller temperature and sample temperature were set to 270 °C or higher, and when the only sample temperature was lowered to 250 °C. Tensile strength did not change significantly with temperature conditions, but elongation decreased with decreasing temperature conditions.

Hot rolling process for explosively welded Mg/Al cladding plates, results of tensile tests for hot rolled samples, and interfacial microstructures of hot rolled samples.