Metallurgical Abstracts on Light Metals and Alloys vol.57

Contributions of multimodal microstructure in the deformation behavior of extruded Mg alloys containing LPSO phase

Koji Hagihara1, 2, Tsuyoshi Mayama3, Michiaki Yamasaki3, Stefanus Harjo4, Toko Tokunaga1, Kazuki Yamamoto1, Mika Sugita1, Kairi Aoyama1, Wu Gong4 and Soya Nishimoto3

1 Department of Physical Science and Engineering, Nagoya Institute of Technology, Gokiso, Nagoya, Aichi 466-8555, Japan

2 Division of Materials and Manufacturing Science, Graduate School of Engineering, Osaka University, 2-1, Yamadaoka, Suita, Osaka 565-0871, Japan

3 Magnesium Research Center & Department of Materials Science, Kumamoto University, 2-39-1, Kurokami, Chuo-ku, Kumamoto, 860-8555, Japan

4 J-PARC Center, Japan Atomic Energy Agency, 2-4 Shirakata, Tokai-mura, Naka-gun, Ibaraki 319-1195, Japan

[Published in International Journal of Plasticity, Vol. 173 (2024), pp. 103865]

https://doi.org/10.1016/j.ijplas.2023.103865

E-mail: hagihara[at]nitech.ac.jp

Key Words: Mg alloy, LPSO-phase, Composite-like strengthening, Work-hardening rate, Neutron diffraction

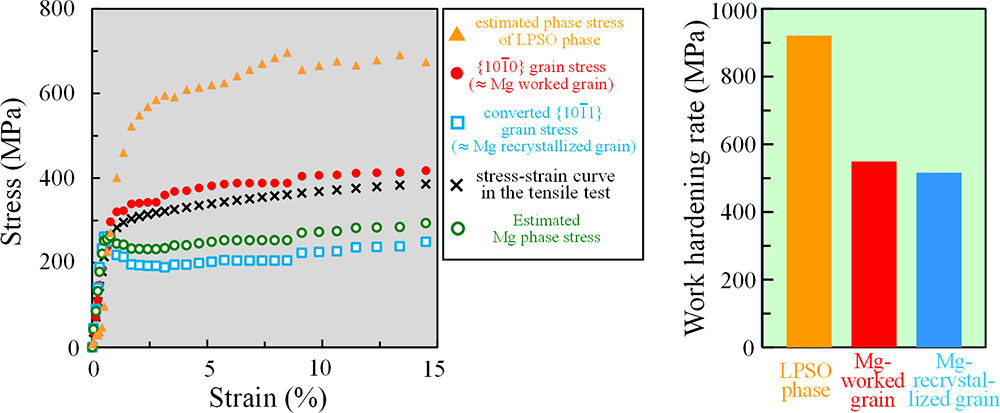

The control mechanisms of the plastic deformation of two-phase extruded alloy composed of Mg and long-period stacking ordered (LPSO) phase were clarified by comparison with those of other Mg solid-solution alloys. The stress-strain curves for each grain in the alloys could be imaginary estimated using neutron diffraction analysis during the tensile test. The deformation behaviors of the worked and recrystallized grains are significantly different in all the Mg-extruded alloys owing to the strong plastic anisotropy in Mg with hexagonal close-packed (hcp) structure. Therefore, the deformation behavior is controlled by a composite-like deformation mechanism. In Mg-Y-Zn ternary alloys, the recrystallized Mg grains exhibited significant lattice softening at the initial stage of yielding. However, the worked grains acted as strengthening components. In the Mg/LPSO two-phase alloy, the composite-like deformation behavior was enhanced, and the LPSO phase significantly contributed to the strengthening of the alloy. Moreover, it was hypothesized that the LPSO phase contributes not only to the alloy’s strength but also to its elongation by increasing the work-hardening rate. Kink-band strengthening in the LPSO phase is believed to be one of the reasons for the increase in the work-hardening rate of the extruded LPSO-phase grains in the Mg/LPSO two-phase alloy.

“Mg grain stress and phase stress” estimated by in-situ neutron diffraction analysis during the tensile deformation of Mg/LPSO two-phase extruded alloy.