Metallurgical Abstracts on Light Metals and Alloys vol.57

Evaluation of the Hot Tribological Properties of the AZ80 Alloy by a V-groove Friction Test

Tatsuya Funazuka*, Shintaro Hosaka**, Kota Yamazaki** and Kuniaki Dohda***

* Faculty of Engineering, University of Toyama, 3190 Gohuku, Toyama, 9308555, Japan

** Graduate School of Science and Engineering for Education, Toyama University, Toyama, Japan

*** Department of Mechanical Engineering, Northwestern University, Evanston, Illinois, 60201, USA

[Published in Proc. ICTMP2024, No. 31]

E-mail: funazuka[at]eng.u-toyama.ac.jp

Key Words: Magnesium alloy, AZ80, Tribology in Manufacturing, Hot forging, Tribotester

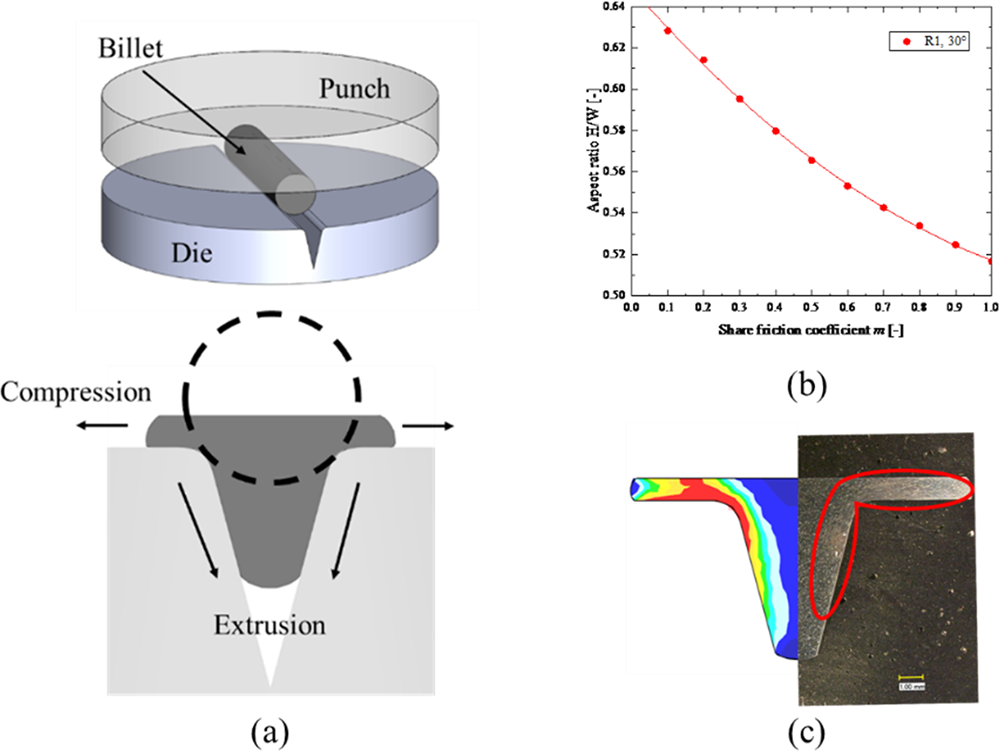

In recent years, the weight reduction of components in the automotive and aircraft industries has become a major issue in achieving sustainable development goals (SDGs), as it is critical to reducing fuel and energy consumption. Magnesium (Mg) alloys have the lowest density among all practical metals and have attracted attention as lightweight materials. For weight reduction, rims and wheels are fabricated by the hot forging of Mg alloys, and the shortening of the die life is a problem because of the high load on the die and the tendency to burn and wear caused by adhesion in the hot forging of Mg. The T-shape compression test (TSCT) can evaluate friction in complex deformations involving both extrusion and compression and can achieve a surface area enlargement greater than 50%. In this study, a hot V-groove friction test based on the TSCT is proposed as a friction test that simulates hot extrusion and forging. The friction coefficient is identified from the aspect ratio of the product after compression, as either longitudinal extrusion or transverse compression is the preferred deformation due to the effects of friction. The proposed test combines extrusion and compression deformation, has a high surface area expansion ratio of a greater than 50%, and produces a two-dimensional deformation in which the circle collapses. In addition, the dimensions and compression ratio can be easily changed. In this study, as part of the development of a V-groove friction test, we examine the tool dimensions and mechanism of adhesion under different temperatures and compression ratios. Using the AZ80 alloy as experimental material and varying the temperature and stroke amount, we investigate the effects of the working temperature on adhesion growth during hot forming.

V-groove friction test for AZ80 (a: Schematic view of V-groove friction test, b: Calibration curve and experimental result, c: Test piece after V-groove friction test).