Metallurgical Abstracts on Light Metals and Alloys vol.57

Effect of Laves Phases on Creep Strength for a Mg-Al-Ca Alloy

You Yamashita* and Yoshihiro Terada*

* Department of Materials Science and Engineering, Tokyo Institute of Technology

[Published in Materials Transactions, Vol. 65 (2024), pp. 583-586]

https://doi.org/10.2320/matertrans.MT-M2024017

E-mail: terada.y.ab[at]m.titech.ac.jp

Key Words: Magnesium alloy, Die-cast, Creep, C15-Al2Ca, C36-(Mg,Al)2Ca

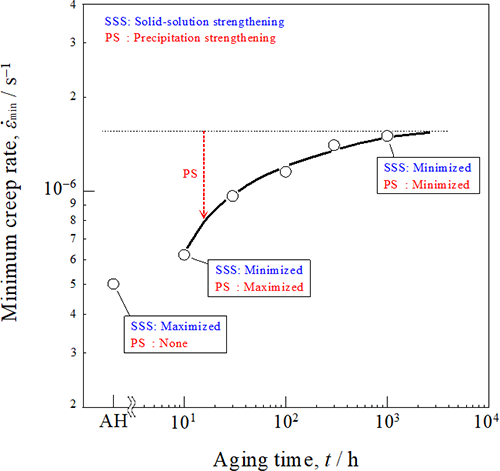

The effect of Laves phases, C36-(Mg,Al)2Ca and C15-Al2Ca, on high-temperature creep strength was quantitatively investigated for the Mg-5.0Al-1.5Ca alloy produced by die-casting. The homogenization treatment at 750 K for 1 h was carried out to divorce the interconnected skeleton of C36 phase, and the aging treatment at 523 K for 1-1000 h was performed to precipitate the C15 phase within the α-Mg grains. The creep tests to evaluate the creep strength were conducted at 447 K and 70 MPa. When the C36 skeleton is divorced, the minimum creep rate dramatically increases by a factor of 330. The coarsening of the C15 phase within the α-Mg grains increases the creep rate by a factor of 2.6. It was identified that the creep strength of the Mg-5.0Al-1.5Ca alloy is predominantly ascribed to the interconnected skeleton of C36 phase rather than the precipitation strengthening of C15 phase.

Figure. Plots of minimum creep rate vs. aging time at 523 K for the Mg-5Al-1.5Ca alloy after homogenization, where the creep tests were carried out at 448 K under a stress of 70 MPa.