Metallurgical Abstracts on Light Metals and Alloys vol.57

Effect of counter punch on formability in two-step compression forming for producing extremely deep cup

Shohei Kajikawa*, Yutaro Umehara*, Takashi Kuboki* and Takashi Iizuka**

* Department of Mechanical and Intelligent Systems Engineering, The University of Electro-Communications

** Faculty of Mechanical Engineering, Kyoto Institute of Technology

[Published in Materials Research Proceedings, Vol. 44 (2024), pp. 616-624]

https://doi.org/10.21741/9781644903254-66

E-mail: s.kajikawa[at]uec.ac.jp

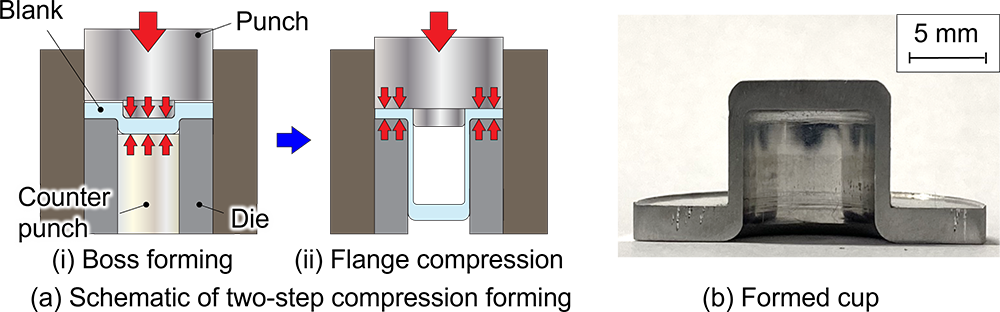

Key Words: Sheet Metal, Compression, Deep Cup, Sheet Forging, Aluminum, FEM

This paper presents two-step compression forming with a counter punch for producing an extremely deep cup with good shape accuracy. In the proposed method, the bottom shape is formed in the first step of the boss forming, and then the side wall is formed in the second step of the flange compression. The influence of the counter punch position in the boss forming was investigated to improve the shape accuracy of the bottom portion in this study. Appropriate counter punch position was predicted in finite element method (FEM) analysis. When the counter punch position was not appropriate, the forming defects, which were the local thinning and the backflow of the material, occurred. Based on the FEM result, the experiments were carried out. The experimental result agreed with the analysis result, and a deep cup with good shape accuracy was successfully formed under the optimum condition.

Deep cup with good shape accuracy was formed by two-step compression forming which is composed of boss forming and flange compression.