Metallurgical Abstracts on Light Metals and Alloys vol.57

Metal additive manufacturing of titanium alloys for control of hard tissue compatibility

Aira Matsugaki, Tadaaki Matsuzaka and Takayoshi Nakano

Division of Materials and Manufacturing Science, Graduate School of Engineering, Osaka University

[Published in Materials Transactions, 2023 Vol. 64 Issue 1 pp. 25-30]

https://doi.org/10.2320/matertrans.MT-MLA2022012

E-mail: matsugaki[at]mat.eng.osaka-u.ac.jp

Key Words: hard tissue compatibility; titanium; bone microstructure; biomedical device; additive manufacturing

Metal additive manufacturing is a powerful tool for providing the desired functional performance of hard tissue biomaterials through a three-dimensional structural design. It is essential to use the interactions between artificial materials and living organisms for functional hard tissue reconstruction. In particular, high-performance anisotropic materials that imitate bone tissue properties are required for recovering bone functionality based on collagen/apatite bone matrix microstructure. This article describes the current development of controlling hard tissue compatibility by additive manufacturing technology of titanium alloys, including our recent findings on bone medical devices for guiding the anisotropic bone microstructure.

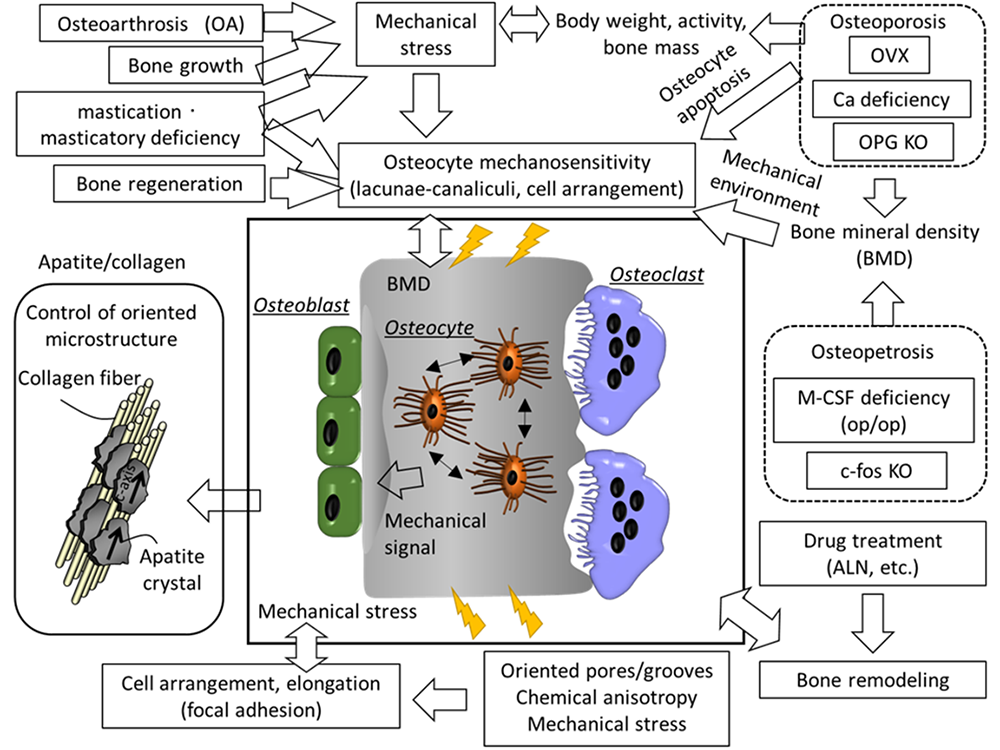

Various factors control bone matrix orientation. Bone orientation is tightly controlled by genes, diseases, cell adhesion mechanisms, and cell-cell communication substances. These are the most important factors to consider in developing hard tissue-compatible bone medical materials.