Metallurgical Abstracts on Light Metals and Alloys vol.57

Resistance spot welding of stainless steel and titanium plates with a supercooled liquid of Zr55Al10Ni5Cu30 metallic glass ribbons

Tokujiro Yamamoto1, Hikaru Kasahara2, Ryosuke Aoki2 and Eito Miura2

1 Department of Fundamental Engineering, Utsunomiya University

2 Graduate Student, Utsunomiya University

[Published in Metallurgical and Materials Transactions A, Vol. 55 (2024), pp. 2589-2595]

https://doi.org/10.1007/s11661-024-07432-6

E-mail: toku[at]cc.utsunomiya-u.ac.jp

Key Words: Dissimilar welding, Metallic glasses, Glass transition, Supercooled liquid, Rapid solidification

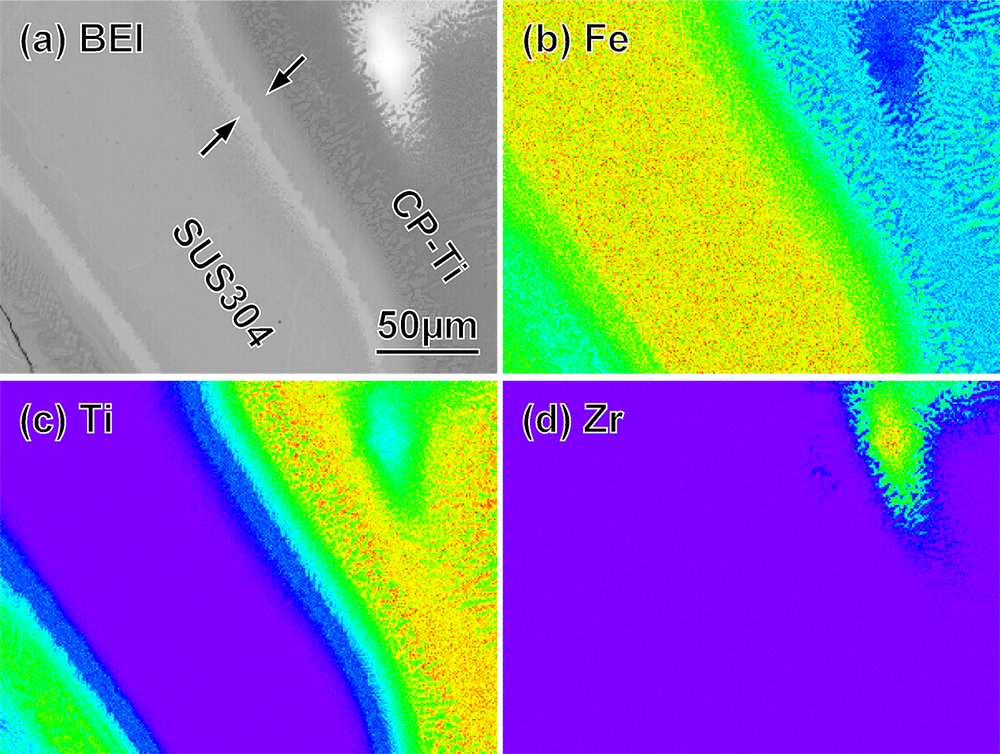

Zr55Al10Ni5Cu30 metallic glass ribbons were interposed between stainless steel and titanium plates as interlayers during dissimilar resistance direct spot welding. Because of the contact resistance between the metallic glass ribbons and the higher resistivity of the metallic glass ribbons, resistance heat was generated in the vicinity of the metallic glass ribbons, causing the ribbons to transition to a supercooled liquid state. By application of electrode force, the supercooled liquid made immediate and contiguous contact with the plates and any excess supercooled liquid was expelled from the nugget, due to the low viscosity of the supercooled liquid. The minimal supercooled liquid remaining between the plates separated the stainless steel from the titanium during welding. The minimal supercooled liquid between the plates also enhanced rapid quenching in the nugget through heat transfer to the plates. As a consequence, the thickness of the Fe-Ti intermetallic compound layers was only less than 20 μm. The enhanced high quenching rate resulted in the suppression of intermetallic compound phase formation, resulting in high joint strength and high reproducibility of mechanical properties in the dissimilar welding of stainless steel and titanium plates.

Microstructure of the boundary between the SUS304 and CP-Ti regions after welding with using Zr-based metallic glass ribbons (a). The corresponding elemental distribution map of (b) Fe, (c) Ti and (d) Zr are also depicted.