Metallurgical Abstracts on Light Metals and Alloys vol.57

Improvement of Fatigue Strength and Rendering Surface Defect Harmless in Pure Titanium by Shot Peening

Kyohei Kawamura*, Toshiya Tsuji** and Koji Takahashi*

* Faculty of Engineering, Yokohama National University

** Shintokogio, LTD

[Published in Kinzoku, Materials Science & Technology, Vol. 94 (2024), pp. 6-11]

E-mail: takahashi-koji-ph[at]ynu.ac.jp

Key Words: Pure titanium, Fatigue strength, Rendering surface defects harmless, Residual stress, Shot peening

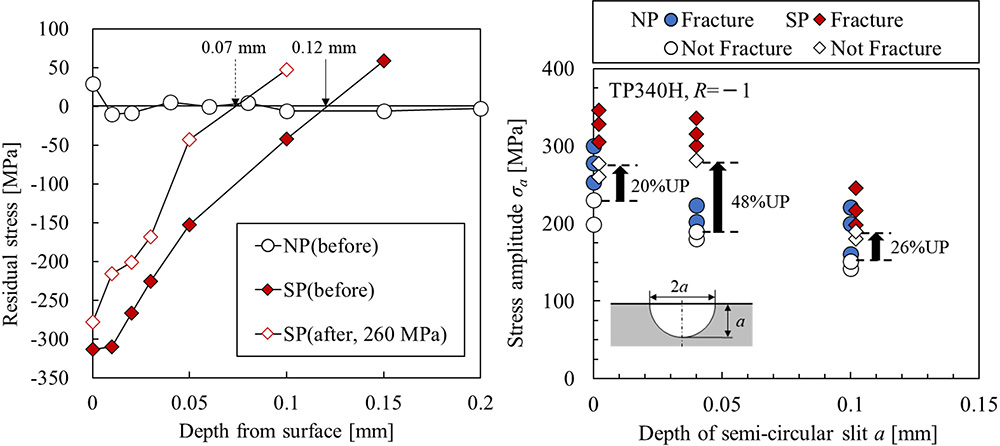

To improve fatigue strength and render surface defects harmless, pure titanium specimens with semicircular slits of 0.04 mm and 0.1 mm depth were shot peened and subjected to plane bending fatigue tests. Shot peening (SP) increased the hardness on the surface and introduced compressive residual stress from the surface to depth about 0.1 mm. Fatigue strength of smooth specimens increased 20%. Fatigue tests showed that surface defects at a depth of 0.04 mm could be rendered harmless by SP, while surface defects at a depth of 0.1 mm could not. The predicted maximum defect size that could be rendered harmless by fracture mechanics was 0.05 mm in depth, which was consistent with the fatigue test results.

The compressive residual stress introduced by shot peening improved the fatigue strength of pure titanium by 20% and rendered harmless surface defects at a depth of 0.04 mm.