Metallurgical Abstracts on Light Metals and Alloys vol.57

Comparison of Mechanical Properties in Ultrafine Grained Commercial-Purity Aluminum (A1050) Processed by Accumulative Roll Bonding (ARB) and High-Pressure Sliding (HPS)

Yongpeng Tang*, **, ***, Toshiki Fujii*, Shoichi Hirosawa*, Kenji Matsuda****, Daisuke Terada***** and Zenji Horita**, ***, ******, *******

* Department of Mechanical Engineering and Materials Science, Yokohama National University, Yokohama 240-8501, Japan

** Department of Materials Science and Engineering, Kyushu University, Fukuoka 819-0395, Japan

*** Graduate School of Engineering, Kyushu Institute of Technology, Kitakyushu 804-8550, Japan

**** Graduate School of Science and Engineering, University of Toyama, Toyama 930-8555, Japan

***** Department of Mechanical Science and Engineering, Chiba Institute of Technology, Narashino 275-0016, Japan

****** Magnesium Research Center, Kumamoto University, Kumamoto 860-8555, Japan

******* Synchrotron Light Application Center, Saga University, Saga 840-8502, Japan

[Published in Materials Transactions, Vol. 64 (2023), pp. 1902-1911]

https://doi.org/10.2320/matertrans.MT-MF2022047

E-mail: hirosawa[at]ynu.ac.jp

Key Words: Severe plastic deformation, Accumulative roll bonding, High-pressure sliding, Grain refinement, Ductility and strength, Strain hardening rate, Strain rate sensitivity

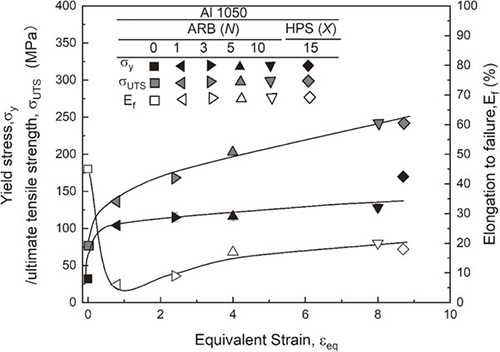

This study presents that A1050 commercial-purity aluminum increases the tensile strength and ductility using the processes of accumulative roll bonding (ARB) and high-pressure sliding (HPS). Both processes yield a similar tensile strength exceeding 240 MPa after processing by ARB for 10 cycles and by HPS for the sliding distance of 15 mm, respectively. The stress-strain behavior is evaluated through microstructure observations and measurements of strain hardening rates. Significant grain refinement with well-defined grain boundaries is responsible for the strength increase. The grain refinement also leads to an increase in strain hardening rate and thus an increase in the ductility.

Yield stress and elongation to failure plotted against equivalent strain at strain rate of 1 × 10-5 s-1.