Metallurgical Abstracts on Light Metals and Alloys vol.57

Effect of Oxide Films on Fatigue Properties of Anodically Oxidized Aluminum Alloys

Takeshi Ando*, Atsuki Komeya*, Miu Hayashi*, Hiroyuki Akebono* and Atsushi Sugeta*

* Graduate School of Advanced Science and Engineering Hiroshima University

[Published in Proceedings of 13th International Fatigue Congress (FATIGUE2022+1) (2023), pp. 233]

E-mail: Akebono[at]hiroshima-u.ac.jp

Key Words: Fatigue, Anodized Coating, Aluminum Alloy, Crack

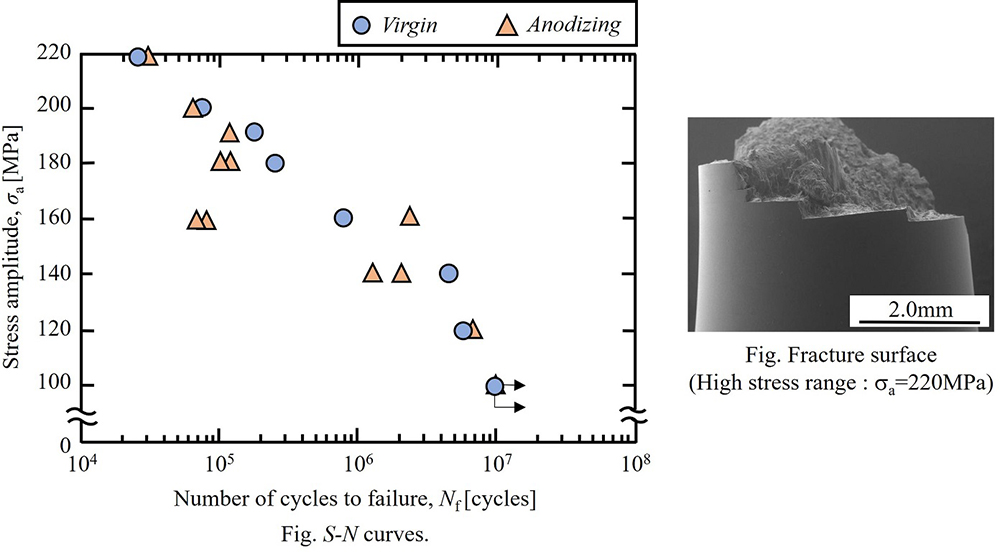

Aluminum alloys are widely used in our daily lives, from large structural parts such as automobiles to small items such as aluminum cans and aluminum foil, because of their light weight and high strength. However, aluminum alloys have the disadvantage of being soft and susceptible to surface damage, which is generally remedied by anodizing. In this study, fatigue tests were conducted with and without anodic oxidation treatment in order to evaluate the strength of anodic oxide. As a result, it was confirmed that anodic oxidation treatment reduced fatigue strength in a certain stress range. It was also inferred that cracks in the oxide film were the cause of the decrease in fatigue strength. Therefore, the condition of crack generation was also discussed by observing the surface condition during tensile and fatigue tests. From these tests, it was confirmed that the oxide film exhibits brittle fracture, and that these cracks lead to the notch effect, which results in the reduction of fatigue strength.

There is no difference in fatigue strength between anodized aluminum alloy and virgin in the regions above 180MPa and below 140MPa. It was confirmed that under axial loading conditions anodizing does not reduce fatigue strength in certain stress amplitude region. In addition, fatigue strength of the anodizing varied at 160 MPa.