Metallurgical Abstracts on Light Metals and Alloys vol.57

Microstructure and mechanical properties of Al/AlN interpenetrating phase composites with different preform porosity

Xiao Yan*, Kenjiro Sugio*, Yongbum Choi*, Tiansheng Wang**, Zhefeng Xu**, Chunzhi Zhao*** and Gen Sasaki*

* Graduate School of Advanced Science and Engineering, Hiroshima University

** State Key Laboratory of Metastable Materials Science and Technology, Yanshan University

*** National Key Laboratory for Precision Hot Processing of Metals, School of Materials Science and Engineering, Harbin Institute of Technology

[Published in Materials Chemistry and Physics 315 (2024) 129029]

https://doi.org/10.1016/j.matchemphys.2024.129029

E-mail: gen[at]hiroshima-u.ac.jp

Key Words: Interpenetrating phase composite, Microstructure, Mechanical properties, Preform porosity

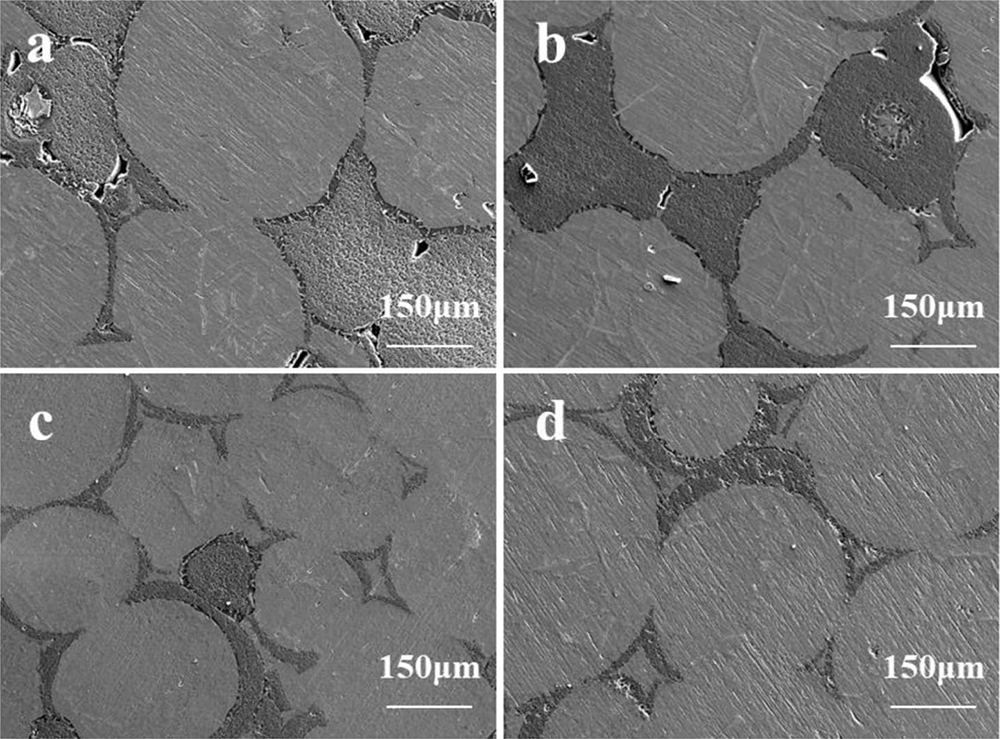

In this work, Al/AlN interpenetrating phase composites (IPCs) were fabricated by infiltrating the alloy melt into AlN preform via low-pressure casting. Open cell porous AlN preforms, fabricated via the slurry infiltration method, and have four different preform porosity were used for IPCs fabrication. The microstructures of porous AlN preforms and Al/AlN interpenetrating phase composites were characterized using scanning electron microscopy (SEM). The phase compositions of preforms and composites were analyzed by X-ray diffraction (XRD). The interface between AlN and Al matrix was found to have no visible defects, indicating good interfacial bonding. Compression tests were conducted, and the results showed that the material strength and toughness increased with increasing porosity. Additionally, the composites changed from brittle fracture to ductile fracture. Nanoindentation tests indicate that an increase in AlN content enhances the hardness of the IPCs components.

Microstructure of composites fabricated by infiltrating molten aluminum alloy into AlN porous bodies with different porosities (a. 71%, b. 76%, c. 79% and d. 84%).