Metallurgical Abstracts on Light Metals and Alloys vol.57

Crystallographic Textures of Al and Al-Mg Alloy Formed by Shot-Peening

Hisashi Sato*, Mami Mihara-Narita*, Yoshimi Watanabe* and Satoshi Motozuka**

* Department of Physical Science and Engineering, Nagoya Institute of Technology

** Department of Materials Science and Engineering, Kyushu Institute of Technology

[Published in Materials Science Forum, Vol. 1106 (2023), pp. 41-47]

https://doi.org/10.4028/p-OMIw3U

E-mail: sato.hisashi[at]nitech.ac.jp

Key Words: Shot-peening (SP), Al, Al-Mg alloy, Surface severe plastic deformation (SSPD), Texture

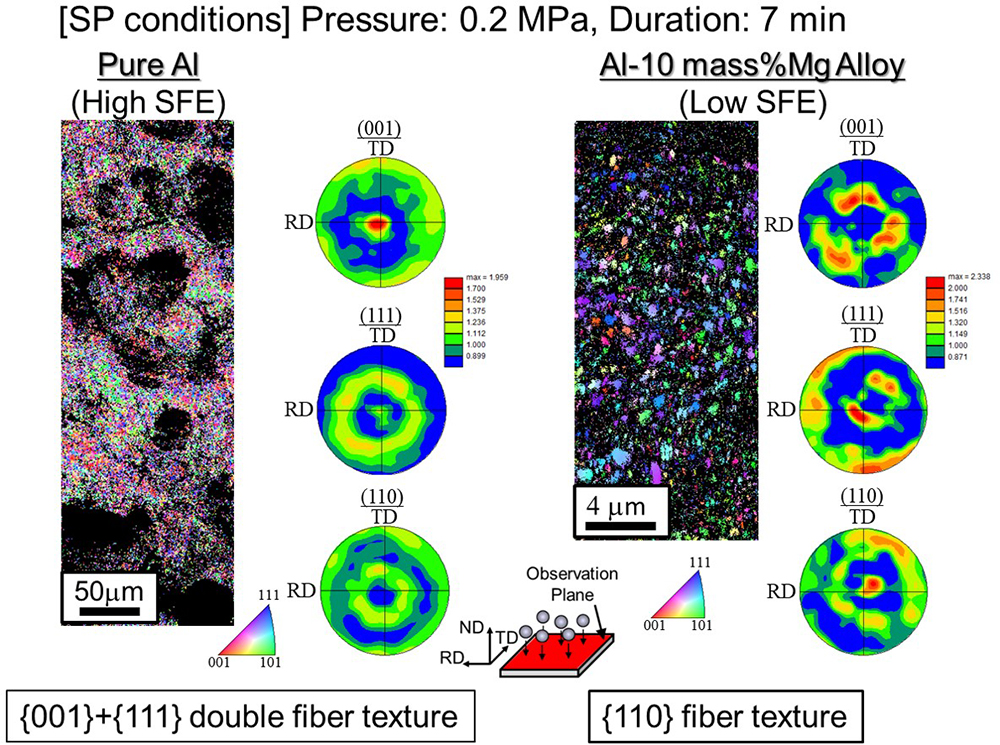

Shot-peening (SP) is well known as surface severe plastic deformation (SSPD) processing technique. In our previous study, it has been reported that a {110} fiber texture, in which the <110> direction is parallel to the plane normal direction of the peened surface, is formed by the SP for the pure Cu plate. Since this crystallographic texture is formed depending on the dislocation slip, the crystallographic texture by the SP would be affected by stacking fault energy (SFE) of the materials. However, effects of the SFE on the crystallographic texture by the SP is not clear. In this study, the crystallographic textures of pure Al and Al-10 mass%Mg alloy by the SP are investigated. The SFE of the pure Al is higher than that of the Al-10 mass%Mg alloy. When the pure Al is SPed, {001}+{111} double fiber texture with the <001> and <111> directions parallel to the plane normal direction of the peened surface is obtained. On the other hand, in the case of Al-10 mass%Mg alloy with the SFE close to the pure Cu, {110} fiber texture is formed as well as the pure Cu. Therefore, it is concluded that the crystallographic texture formed by the SP is influenced by the SFE.

Inverse pole figure maps, and (001), (111) and (110) pole figures of pure Al and Al-10 mass%Mg alloy plates SPed for 7 min at peening pressure of 0.2 MPa. The observation is performed on the peened surface.