Metallurgical Abstracts on Light Metals and Alloys vol.57

Effect of Partial Substitution of Zr for Ti Solvent on Young’s Modulus, Strength, and Biocompatibility in Beta Ti Alloy

Yusuke Nomura1, Mio Okada1, Tomoyo Manaka2, Taiki Tsuchiya1, Mami Iwasaki3, Kenji Matsuda1 and Takuya Ishimoto2

1 Department of Materials Design and Engineering, Faculty of Sustainable Design, University of Toyama

2 Aluminium Research Center, University of Toyama

3 Department of Mechanical Engineering, University of Toyama

[Published in Materials, Vol. 17 (2024), 2548]

https://doi.org/10.3390/ma17112548

E-mail: ishimoto[at]sus.u-toyama.ac.jp

Key Words: Ti alloys, low Young’s modulus, high strength, solid solution strengthening, biomaterials

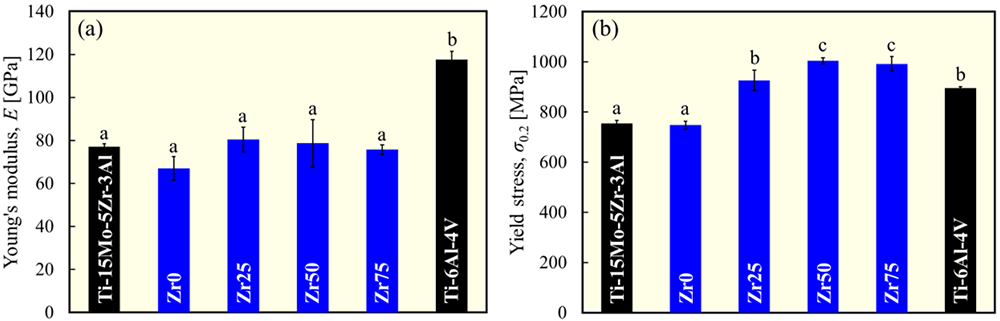

In orthopedics and dentistry, there is an urgent need to obtain low-stiffness implants that suppress the stress shielding caused by the use of metallic implants. In this study, we aimed to fabricate alloys that can reduce the stiffness by increasing the strength while maintaining a low Young’s modulus based on the metastable β-Ti alloy. We designed alloys in which Ti was partially replaced by Zr based on the ISO-approved metastable β-Ti alloy Ti-15Mo-5Zr-3Al. All alloys prepared by arc melting and subsequent solution treatment showed a single β-phase solid solution, with no formation of the ω-phase. The alloys exhibited a low Young’s modulus equivalent to that of Ti-15Mo-5Zr-3Al and a high strength superior to that of Ti-15Mo-5Zr-3Al and Ti-6Al-4V. This strengthening was presumed to be due to solid-solution strengthening. The biocompatibility of the alloys was as good as or better than that of Ti-6Al-4V. These alloys have potential as metallic materials suitable for biomedical applications.

Variations in (a) Young's modulus and (b) yield stress of each alloy. a, b, and c indicate statistically homogeneous subgroups with P > 0.05 (Tukey HSD multiple comparison test).