Metallurgical Abstracts on Light Metals and Alloys vol.57

Microstructure and enhanced strength and ductility of Ti-Zr-O alloys prepared by a laser powder bed fusion process

Akira Otsua, Asami Doia, Tetsuhiko Ondaa, Takahiro Kimurab, Takayuki Nakamotob and Zhong-Chun Chena

a Department of Mechanical and Aerospace Engineering, Graduate School of Engineering, Tottori University, Koyama-minami 4-101, Tottori 680-8552, Japan

b Osaka Research Institute of Industrial Science and Technology, 2-7-1 Ayumino, Izumi-City, Osaka 594-1157, Japan

[Published in Additive Manufacturing, Vol. 85 (2024), Article ID 104170]

https://doi.org/10.1016/j.addma.2024.104170

E-mail: chen[at]tottori-u.ac.jp

Key Words: Titanium-zirconium-oxygen alloy, Laser powder bed fusion, Solid solution strengthening, Yield strength, Biocompatibility

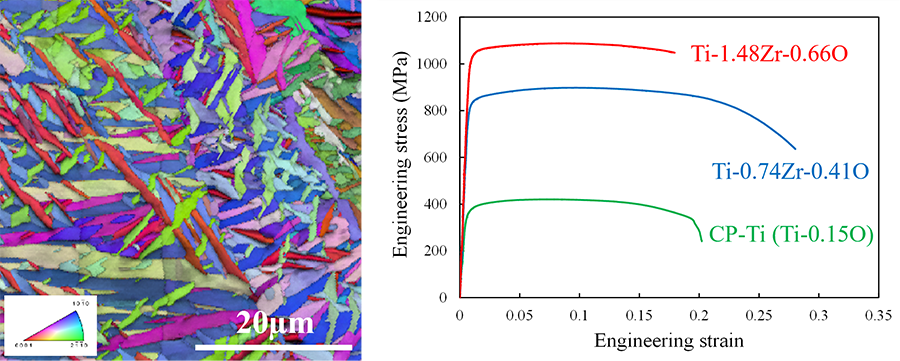

Abstract: Non-toxic and biocompatible Ti-Zr-O alloys with excellent comprehensive properties of strength and ductility were prepared from Ti-ZrO2 powder mixtures by a laser powder bed fusion (LPBF) process. The substitutional Zr atoms and interstitial O atoms, formed by decomposition of ZrO2 during laser irradiation, were dissolved into crystal lattice of Ti, resulting in significant increases in lattice constant c and axial ratio c/a. The Ti-Zr-O alloys were characterized by fine needle-like microstructure with weakened texture compared to pure Ti. The needle-like microstructure may be generated through the growth of α-nuclei according to the Burgers orientation relationship during β→α phase transformation, and the reduction of crystallographic anisotropy in the Ti-Zr-O alloys is due to the formation of α grains with multiple variants. The LPBFed Ti-Zr-O alloys exhibited significantly enhanced strength and maintained good ductility, overcoming the strength-ductility trade-off dilemma. For example, the yield strength and ultimate tensile strength (UTS) of the Ti-1.48Zr-0.66O alloy reached 1014 MPa and 1073 MPa, respectively, and its elongation at fracture remained at 17%. The strength enhancement is due to the solid solution strengthening of O and Zr and grain refinement strengthening, of which the solid solution strengthening of interstitial O atoms is the most dominant contributor to the improvement in strength of the LPBFed Ti-Zr-O alloys. The good ductility is mainly attributed to the activation of pyramidal slips due to reduced critical resolved shear stress (CRSS) ratios between pyramidal and prismatic planes, especially dislocation slips along <c+a> directions on the pyramidal planes due to the fine-grained microstructure. The activation of multiple slip systems, including prismatic and pyramidal slips, contributes to the improved ductility of the LPBFed Ti-Zr-O alloys.

Representative microstructure and engineering stress-strain curves of as-built Ti-Zr-O alloys.