Metallurgical Abstracts on Light Metals and Alloys vol.57

Fabrication of Magnetic Pulse Welding Sheets of Aluminum Alloy and GA Steel Plates Subjected to Film Removal Treatment and Their Welding Property

Ryo Kanematsu*, Takashi Sakai*, Yuki Mizunuma*, Ryosuke Yamagata*, Keigo Okagawa** and Takaomi Itoi*

* Course in Mechanical Engineering, Graduate School of Engineering, Chiba University, 1-33 Yayoi-cho, Inage-ku, Chiba-shi, Chiba 263-8522, Japan

** Tokyo Metropolitan College of Industrial Technology, 1-10-40, Higashioi, Shinagawa-ku, Tokyo 140-0011, Japan

[Published in J. Japan Inst. Met.Mater., Vol. 74, (2024), pp. 251-254]

https://doi.org/10.2320/matertrans.MT-L2024016

E-mail: itoi[at]faculty.chiba-u.jp

Key Words: Magnetic pulse welding; 6061-T6; GA steel; Microstructure; Corrosion test

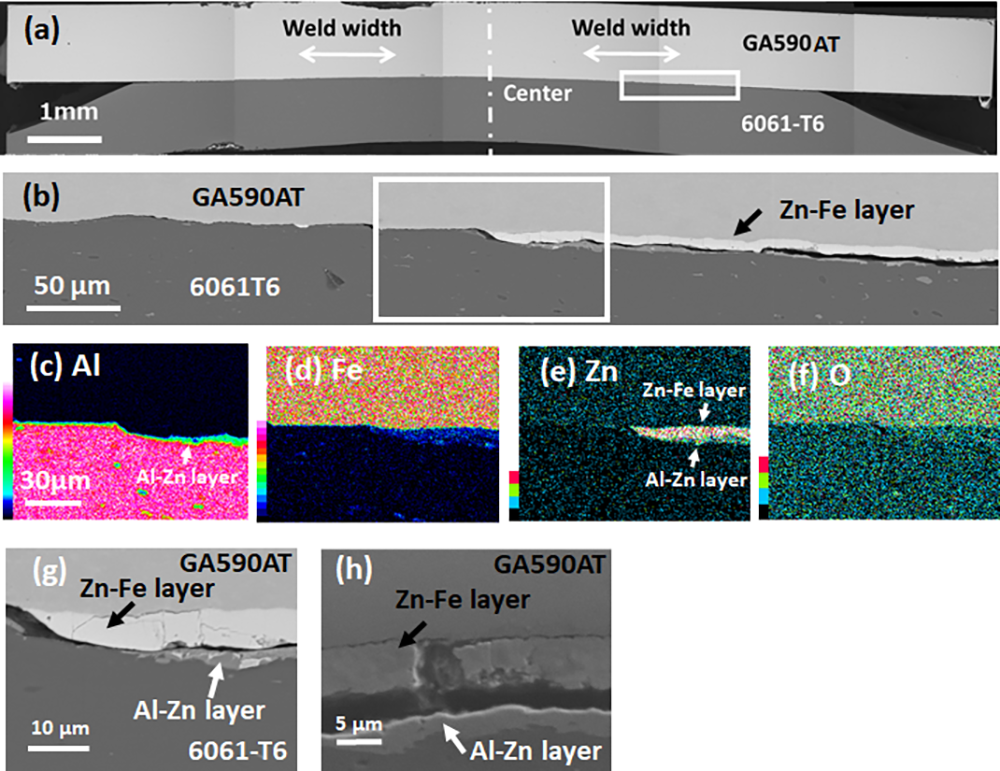

The GA steel sheets with various strengths (590, 780, and 980 MPa classes) from which the Zn-Fe film was removed and 6061-T6 sheets were lap joined. Before welding the GA steel sheets, a Zn-Fe film with a width of 5 mm was removed by grinding or acid treatment. In the case of acid treatment with dilute sulfuric acid, the film was removed within 3 minutes. With either film removal method, the film was removed and a lap joint between GA steel sheet and 6061-T6 sheet was able to be achieved.

The corrosion resistance of the lap joint sheets was investigated through salt spray test for 120-hours. The results showed that even under conditions where GA steel plates corrode, the weld interface did not corrode and bonding strength remained as well as before the corrosion test.