Metallurgical Abstracts on Light Metals and Alloys vol.57

Effect of surface characteristics on the axial fatigue properties and wear resistance of Ti-6Al-4V alloy nitrided by gas blow induction-heating

Shogo Takesue*, Ryu Suyama **, Motoaki Hayama** , Yoshihiko Koyanagi***, Yoshitaka Misaka**** and Jun Komotori*****

* Department of Mechanical Engineering, Kyoto Institute of Technology, Matsugasakigoshokaidocho, Sakyo-ku, Kyoto-shi, Kyoto, 606-8585, Japan

** Graduate School of Science and Technology, Keio University, 3-14-1 Hiyoshi, Kohoku-ku, Yokohama-shi, Kanagawa, 223-8522, Japan

*** Daido Steel Co., Ltd., 30-2 Daido-cho, Minami-ku, Nagoya-shi, Aichi, 457-8545, Japan

**** Neturen Co., Ltd., 7-4-10 Tamura, Hiratsuka-shi, Kanagawa, 245-0013, Japan

***** Department of Mechanical Engineering, Keio University, 3-14-1 Hiyoshi, Kohoku-ku, Yokohama-shi, Kanagawa, 223-8522, Japan

[Published in Engineering Failure Analysis, Vol. 157,107933 (2024)]

https://doi.org/10.1016/j.engfailanal.2023.107933

E-mail: stakesue [at] kit.ac.jp

Key Words: Mechanical Engineering; Mechanical structural component; Titanium alloys

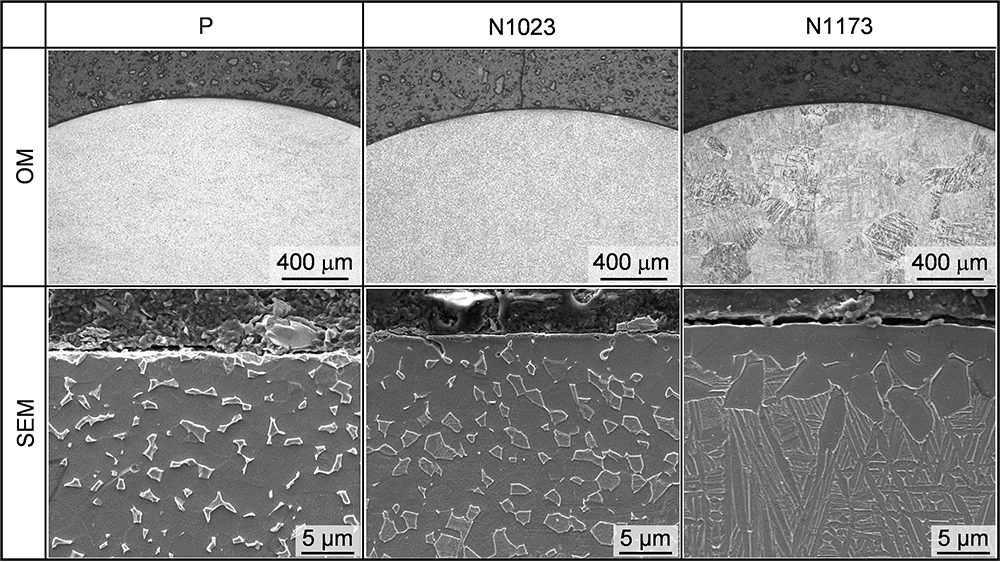

The effects of surface characteristics on the axial fatigue properties and wear resistance of the GBIH-nitrided titanium alloy were investigated to improve the fatigue strength and wear resistance of Ti-6Al-4V alloy rapidly nitrided by induction-heating in a nitrogen atmosphere with blowing nitrogen gas (GBIH-nitriding). The fatigue strength of the GBIH-nitrided Ti-6Al-4V alloy was lower than that of the mirror-polished specimen owing to the formation of a brittle nitrogen compound layer and grain coarsening. Fatigue tests using specimens prepared by combining GBIH-nitriding and particle collision treatments revealed that the formation of nitrogen diffusion layers at the outermost surface and the generation of compressive residual stress without forming surface asperities increased the fatigue strength of the GBIH-nitrided Ti-6Al-4V alloy. Moreover, the formation of a nitrided layer and suppression of surface asperities effectively improved the wear resistance of the Ti-6Al-4V alloy. Therefore, formation of a nitrogen diffusion layer and the introduction of compressive residual stress without grain coarsening, a compound layer, and surface asperities increased the fatigue strength and wear resistance of the GBIH-nitrided alloy.

Fig. Optical and SEM micrographs of longitudinal sections of polished and gas blow induction-heating nitrided specimens at 1023 K and 1173 K.