Metallurgical Abstracts on Light Metals and Alloys vol.57

Anisotropic deformation behavior during cup drawing at room temperature of a ZX10 Magnesium alloy sheet

Takayuki Hama1, Koichi Higuchi1 and Yuto Nakata1

1 Graduate School of Energy Science, Kyoto University, Japan

[Published in Materials Research Proceedings, Vol. 28, (2023), pp. 711-716]

https://doi.org/10.21741/9781644902479-77

E-mail: hama[at]energy.kyoto-u.ac.jp

Key Words: Magnesium Alloy, Room-Temperature Cup Drawing, Twinning, Lankford Value, Thickness Strain

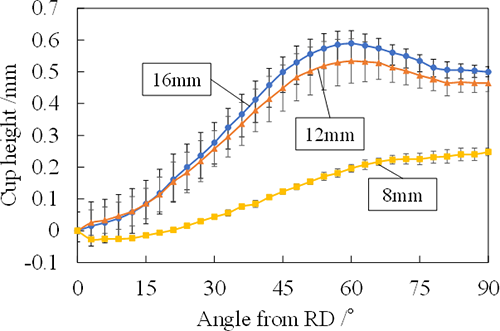

Magnesium (Mg) alloy sheets have low density and high specific strength; thus, they are expected to facilitate weight reduction of structural components. However, because of the strong crystal anisotropy of the hexagonal structure and the strong basal texture observed in typical rolled Mg alloy sheets, their press formability at room temperature is low. To improve the room-temperature press formability, ZX series Mg alloy sheets that weakened the basal texture have recently been developed. The plastic deformation behavior of a rolled Mg-1.5mass%Zn-0.1mass%Ca (ZX10Mg) alloy sheet was studied in a previous study [7], and it was reported that the plastic deformation behavior showed strong in-plane anisotropy and differed notably from that of AZ series rolled Mg alloy sheets. In the present study, cylindrical cup drawing of a ZX10Mg alloy sheet was performed at room temperature and the drawability was examined in terms of cup height distributions, strain evolution, and texture evolution. The cup height differed significantly between the rolling and transverse directions. The thickness at the cup edge was the largest in the rolling direction and the smallest in the transverse direction. The magnitude relationship of the thickness correlated with the Lankford values under compression. The mechanism that yielded the difference in texture evolution was also discussed.

Distributions of cup height in the circumferential direction at punch strokes of 8 mm, 12 mm, and 16 mm.