Metallurgical Abstracts on Light Metals and Alloys vol.57

The effects of oxygen addition on microstructure and mechanical properties of Ti-Mo alloys for biomedical application

Sengo Kobayashi and Satoshi Okano

Graduate School of Science and Engineering, Ehime University

[Published in Front. Bioeng. Biotechnol., (2024), pp. 01-13]

https://doi.org/10.3389/fbioe.2024.1380503

E-mail: kobayashi.sengo.me[at]ehime-u.ac.jp

Key Words: Titanium alloy, Oxygen, Microstructure, Mechanical property, Biomedical application

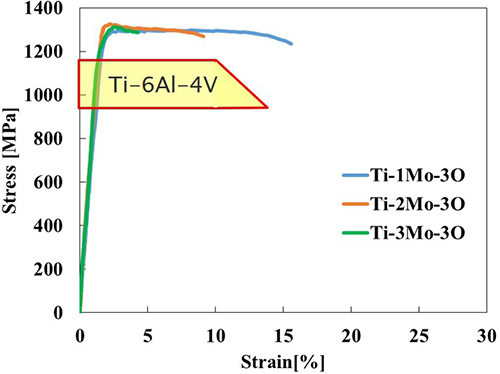

The effective use of oxygen as an alloying element in Ti alloys is attractive due to the reduction of production cost and the increase in strength and hardness of the alloy. Although the oxygen addition in a Ti alloy increases strength and hardness, it may induce brittleness. An appropriate combination of alloying elements and thermomechanical treatment must be clarified for using oxygen as an alloying element. Ti-(0, 1.0, 2.0, 3.0)Mo-(0, 1.5, 3.0)O alloys were developed, and their microstructure and mechanical properties were examined. Ti-1Mo-3O alloy exhibited fine grains of α+β two phases having the tensile strength of 1,297 MPa with 15.5% for total strain at fracture. The Ti-1Mo-3O alloy has 1.5 times the tensile strength and almost the same total strain as the Ti-6Al-4V ELI alloy. Ti-(1.0, 2.0, 3.0)Mo-1.5O alloys also have excellent mechanical properties, with a tensile strength of about 1,050–1,150 MPa and a total strain of about 20%–25%. In order to develop a high strength and moderate ductility Ti-Mo alloy using oxygen as an alloying element, the microstructure should have fine grains of α+β two phases with proper volume fraction of α and β phases and specific molybdenum concentration in β phase.

Stress-strain curve of Ti-(1, 2, 3)Mo-3O alloy. The typical mechanical property range of Ti-6Al-4V alloy is shown as a shaded area. The developed alloys have higher strength than the Ti-6Al-4V alloy and moderate ductility.