Metallurgical Abstracts on Light Metals and Alloys vol.54

Quantitative monitoring of the environmental hydrogen embrittlement of Al-Zn-Mg-based aluminum alloys via dynamic hydrogen detection and digital image correlation

Keitaro Horikawa*

*Department of Mechanical Science and Bioengineering, Osaka University

[Published in Scripta Materialia, Vol. 199 (2021), 113853]

https://doi.org/10.1016/j.scriptamat.2021.113853

E-mail: horikawa[at]me.es.osaka-u.ac.jp

Key Words:Al-Zn-Mg alloys, Hydrogen embrittlement

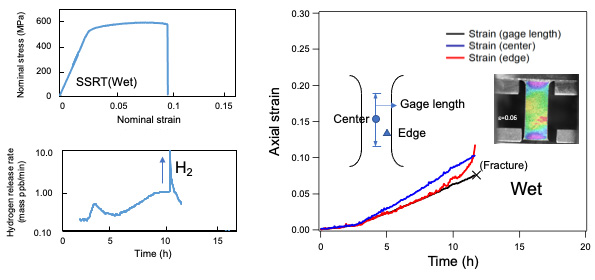

In this study, a novel analytical system was developed to monitor the environmental hydrogen embrittlement of Al-Zn-Mg-based aluminum alloys dynamically and quantitatively under atmospheric air pressure. The system involves gas chromatography using a SnO2-based semiconductor hydrogen sensor, a digital image correlation step, and the use of a slow strain rate testing machine. Use of this system revealed that hydrogen atoms are generated during the plastic deformation of Al-Zn-Mg alloys caused by the chemical reaction between the water vapor in air and the alloy surface without oxide films. Digital image correlation also clarified that the generated hydrogen atoms caused numerous localized grain boundary cracks on the specimen surface, resulting in a localized grain boundary fracture. The amount of hydrogen atoms evolved from the embrittled fracture surface was 2.7 times as high as that from the surface without embrittlement.

Hydrogen release behavior during SSRT, together with change in the local axial strain under Wet condition of an Al-Zn-Mg alloy.