Metallurgical Abstracts on Light Metals and Alloys vol.54

Influence of residual stress around constituent particles on recrystallization and grain growth in Al-Mn based alloy during annealing

Sung-Jin Park* and Shinji Muraishi**

*Dept. of Materials Science and Technology, Tokyo Institute of Technology (present: LG Electronics, Korea)

**Dept. of Materials Science and Technology, Tokyo Institute of Technology

[Published in Materials, Vol. 14 (2021), 1701]

https://doi.org/10.3390/ma14071701

E-mail: muraishi.s.aa[at]m.titech.ac.jp

Key Words:Plastic Deformation, Dislocations, Inhomogeneity Problem, Residual Stress, Recrystallization

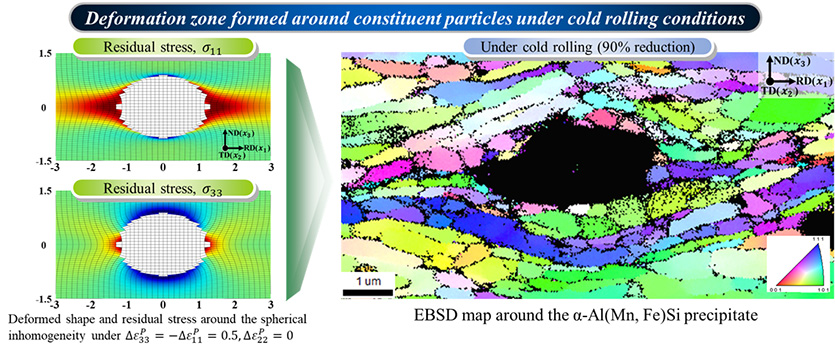

Effect of the residual stress on the recovery and recrystallization behaviors of the cold-rolled AA3003 aluminum alloy was investigated. The evolution of deformed microstructure and dislocation density characterized by TEM and Synchrotron X-ray measurements found that the change in the ratio between low angle grain boundaries (LAGBs) and high angle grain boundaries (HAGBs) during annealing is varied depending on the initial dislocation density, where the value of HAGB/LAGBs ratio is amounted to be about 0.8 in maximum. The nucleation and growth rate of the recrystallized grains are strongly dependent on the net driving pressure associated with dislocation density increased by the amount of reduction. EBSD analysis revealed that the deformed zone composed of the fine equi-axed grains with large misorientation angles would be formed in the vicinity of the constituent particles, which is consistent with the region of the large residual stress and total displacement predicted by Eshelby inhomogeneity problem under cold rolling condition.

Prediction of deformed shape and strain disturbance inside/outside the precipitate under cold rolling (left). EBSD colour coded map of the plastic deformation of the matrix phase around the inhomogeneity (right).