Metallurgical Abstracts on Light Metals and Alloys vol.54

Continuous production of dissimilar alloy porous aluminum by conveyor with optical heating

Masataka OHASHI*, Yoshihiko HANGAI*, Hironao MITSUGI*, Kenji AMAGAI* and Takao UTSUNOMIYA**

*Faculty of Science and Technology, Gunma University

**Faculty of Engineering, Shibaura Institute of Technology

[Published in Journal of The Japan Institute of Light Metals, Vol. 71 (2021), pp. 177–179]

https://www.jstage.jst.go.jp/article/jilm/71/4/71_710404/_article/-char/en

E-mail: t15302020[at]gunma-u.ac.jp

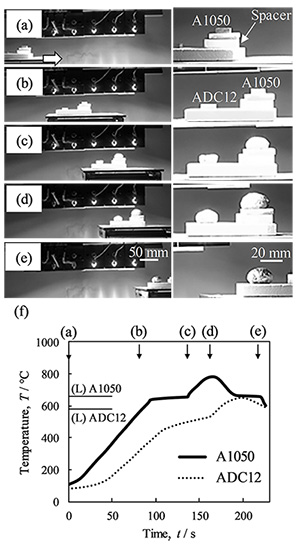

Key Words:porous aluminum, foam, friction stir welding, conveyor, optical heating

Porous aluminum is multifunctional metal materials with light weight and high energy absorption properties. In our previous study, it was shown that continuously production of same alloy porous aluminum by continuously foaming of precursors using a conveyor with optical heating was possible. In this study, continuously foaming of dissimilar alloy precursors on same line was investigated. It is difficult to foam dissimilar alloy precursors on same line because their liquidus temperatures are different. So each heat input of precursor was adjusted by changing distance between precursor and halogen lamps. Two types of precursors, commercially pure aluminum (A1050) and die-casting aluminum alloy (ADC12), were fabricated via the friction stir welding route. Continuously production of dissimilar alloy porous aluminums was carried out by passing of precursors below heating area of halogen lamps. It was found that different alloy aluminum precursors can be continuously foamed on the same line. The obtained porous aluminum had porosity with approximately 80% and good pore structures.

(a) - (e) foaming behavior and (f) temperature history of A1050 and ADC12 precursors (A1050: d = 25 mm, ADC12: d = 40 mm).