Metallurgical Abstracts on Light Metals and Alloys vol.54

Fabrication of two-layered aluminum foam with closed-cell and open-cell structures and shaping of closed-cell layer by press forming immediately after foaming

Yoshihiko Hangai*, Mizuki Ando*, Masataka Ohashi* and Kenji Amagai*

*Graduate of Science and Technology, Gunma University

[Published in Metals, Vol. 11 (2021), No. 140]

https://doi.org/10.3390/met11010140

E-mail: hanhan[at]gunma-u.ac.jp

Key Words:functionally graded materials, cellular materials, sintering; press forming

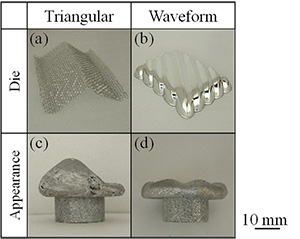

Two-layered aluminum foam consisting of both closed and open cells is expected to improve the functionality of aluminum foam, because the cells have different morphologies and characteris-tics. In this study, press forming of the closed-cell layer of the two-layered aluminum foam im-mediately after foaming was performed to shape the closed-cell layer. By measuring the temper-atures of the two layers during foaming, we found that it is necessary to use aluminum alloy with a higher melting point for the open-cell layer than that for the closed-cell layer to foam the closed-cell layer. In the press forming experiments, the closed-cell layer could be shaped by press forming while the shape of the open-cell layer was maintained.

Press formed dies and obtained AC4CH/pAl samples. (a) Triangular die. (b) Waveform surface die. (c) Triangular AC4CH/pAl sample. (d) Waveform surface AC4CH/pAl sample.