Metallurgical Abstracts on Light Metals and Alloys vol.54

Jointing of porous aluminum by press forming of multiple precursors during foaming process

Masataka OHASHI*, Yoshihiko HANGAI*, Kenji AMAGAI*, Masaaki MATSUBARA*, Ryosuke SUZUKI*, Takao UTSUNOMIYA** and Nobuhiro YOSHIKAWA***

*Faculty of Science and Technology, Gunma University

**Faculty of Engineering, Shibaura Institute of Technology

***Institute of Industrial Science, The University of Tokyo

[Published in Journal of The Japan Institute of Light Metals, Vol. 70 (2020), pp. 517–522]

https://www.jstage.jst.go.jp/article/jilm/70/11/70_701103/_article/-char/en

E-mail: t15302020[at]gunma-u.ac.jp

Key Words:foam, jointing, press forming, friction stir welding, bending test

Porous aluminum is a multifunctional metal material with a light weight and high energy absorption. In our previous study, it was shown that press forming during the foaming of a precursor can form porous aluminum while maintaining its porous structure. In this study, the jointing of porous aluminum by press forming during the foaming of multiple precursors was investigated. The precursors were fabricated via the friction stir welding route. The jointing and shaping of porous aluminum were simultaneously carried out by press forming of the precursors with maintaining their porous structures. From a four-point bending test of the obtained samples, the joint strength was found to be equivalent to the strength of the base porous aluminum. No oxide films were observed at the fracture surfaces generated at the surface of the precursors, which prevented jointing between multiple porous aluminum while porous structures were obtained, which indicated good jointing.

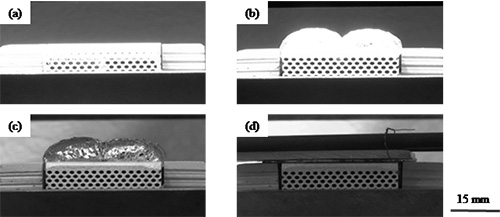

Foaming and press forming behaviors: (a) at start of start heating, (b) foaming, (c) at end of heating, (d) press forming.