Metallurgical Abstracts on Light Metals and Alloys vol.54

Press forming of aluminum foam during foaming using pin screen mold

Yoshihiko HANGAI*, Takumi TOMARU*, Masataka OHASHI*, Kenji AMAGAI*, Takao UTSUNOMIYA** and Nobuhiro YOSHIKAWA***

*Faculty of Science and Technology, Gunma University

**Faculty of Engineering, Shibaura Institute of Technology

***Institute of Industrial Science, The University of Tokyo

[Published in Journal of The Japan Institute of Light Metals, Vol. 70 (2020), pp. 194–196]

https://www.jstage.jst.go.jp/article/jilm/70/5/70_700503/_article/-char/en

E-mail: hanhan[at]gunma-u.ac.jp

Key Words:foam, press forming, friction stir welding, X-ray computed tomography

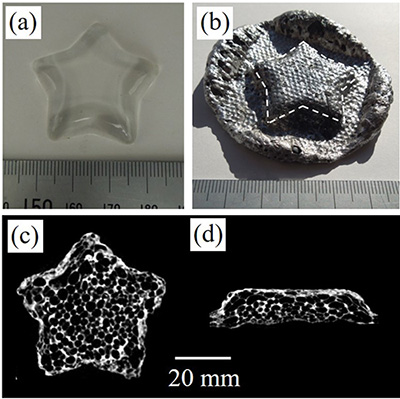

The precursor foaming process is one of the fabrication processes used for the fabrication of aluminum foam. In this study, the shaping of the aluminum foam was conducted by press forming during foaming precursor. A pin screen mold was proposed for the die of the press forming. It was shown that the pin screen mold could be used for the die of the press forming of the aluminum foam, and star-shaped aluminum foam can be obtained. From X-ray computed tomography (CT) observation, there is little effect of press forming by using pin screen mold on the pore structures of the obtained aluminum foam.

Obtained aluminum foam. (a) Star shaped model. (b) Photo of star shaped aluminum foam. (c) Horizontal cross-sectional X-ray CT image of (b). (d) Vertical cross-sectional X-ray CT image of (b).