Metallurgical Abstracts on Light Metals and Alloys vol.54

Developing Age-Hardenable Al-Zr Alloy by Ultra-Severe Plastic Deformation: Significance of Supersaturation, Segregation and Precipitation on Hardening and Electrical Conductivity

Abbas Mohammadi*, Nariman A. Enikeev**, Maxim Yu. Murashkin**, Makoto Arita*** and Kaveh Edalati*

*WPI International Institute for Carbon-Neutral Energy Research (WPI-I2CNER), Kyushu University, Fukuoka 819-0395, Japan

**Institute of Physics of Advanced Materials, Ufa State Aviation Technical University, Ufa 450008, Russia; Laboratory for Mechanics of Bulk Nanostructured Materials, Saint Petersburg State University, Peterhof, Saint Petersburg 198504, Russia

***Department of Materials Science and Engineering, Faculty of Engineering, Kyushu University, Fukuoka 819-0395, Japan

[Published in Acta Materialia, Vol. 203 (2021), p. 116503]

https://doi.org/10.1016/j.actamat.2020.116503

E-mail: kaveh.edalati[at]kyudai.jp

Key Words:high-pressure torsion (HPT), age hardening; aluminum-zirconium intermetallics, thermal stability, electrical conductivity

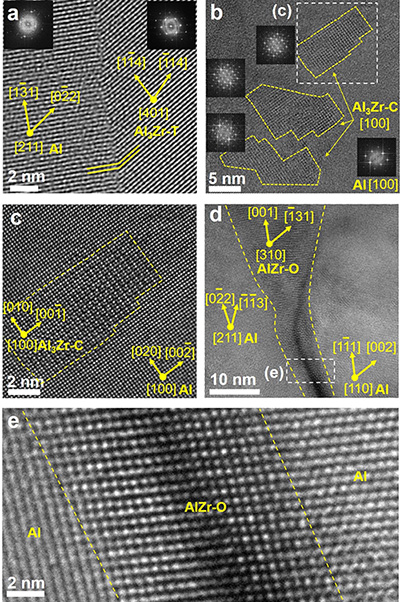

The aluminum-zirconium (Al-Zr) alloys are of interest because of their superior thermal stability and good electrical conductivity, but their main drawback is their rather low hardness (<75 Hv) even after severe plastic deformation (SPD). These alloys, which are actually composites of Al and Al3Zr intermetallics (D023 tetragonal structure), do not show age-hardening behavior due to the immiscibility of Zr in Al. In this study, ultra-SPD with shear strains up to 40,000, realized by high-pressure torsion (HPT), is employed to generate supersaturated solid solution in an Al-Zr alloy. Subsequent aging leads to unusual precipitation of AlZr precipitates at grain boundaries (Bf orthorhombic structure) and of coherent metastable Al3Zr precipitates within grain interiors (L12 cubic structure) (Figs. 1). It is found that the supersaturation of Zr in Al by ultra-SPD is controlled by an ultrafast dynamic diffusion which is comparable to surface diffusion, while the formation of precipitates by static aging is controlled by lattice and pipe diffusions. These microstructural features provide exceptional increase in hardness up to 148 Hv, great thermal stability up to 523 K and reasonable electrical conductivity up to 35 %IACS (Fig. 2). Detailed analysis shows that ~30% of this hardening is caused by precipitation strengthening, while extra hardening is achieved due to nanograin formation, grain-boundary segregation and dislocation accumulation. This study introduces a rational approach to produce novel age-hardenable Al alloys with high thermal stability and reasonable electrical conductivity by application of ultra-SPD.

Fig. 1 Transmission electron microscopy of sample processed by HPT and aged at 503 K. (a) Al/Al3Zr boundary, (c) coherent Al3Zr precipitates in Al grain, (d) magnified view of Al3Zr precipitate, (e) thin layer of AlZr in Al/Al boundary and (f) magnified view of AlZr. Al3Zr-T, Al3Zr-C and AlZr-O denote Al3Zr with D023 structure, Al3Zr with L12 structure and AlZr with Bf structure, respectively.

Fig. 2 Electrical conductivity against microhardness for Al-5%Zr alloy processed by HPT and aging, in comparison with reported data in literature.