Metallurgical Abstracts on Light Metals and Alloys vol.54

Fabrication of be-ta Ti alloys without pre-alloyed powders via SLM

Mitsuharu Todai*, Takeshi Nagase** and Takayoshi Nakano**

*Department of Environmental Materials Engineering, National Institute of Technology, Niihama College, 7-1 Yagumo-cho Niihama, Ehime 792-8580, Japan

**Division of Materials and Manufacturing Science, Graduate School of Engineering, Osaka University, 2-1 Yamadaoka, Suita, Osaka 565-0871, Japan

[Published in Materials Science Forum, Vol. 1016 (2021), pp. 1797–1801]

https://doi.org/10.4028/www.scientific.net/MSF.1016.1797

E-mail: todai[at]mat.niihama-nct.ac.jp

Key Words:be-ta Ti alloys, Additive Manufacturing

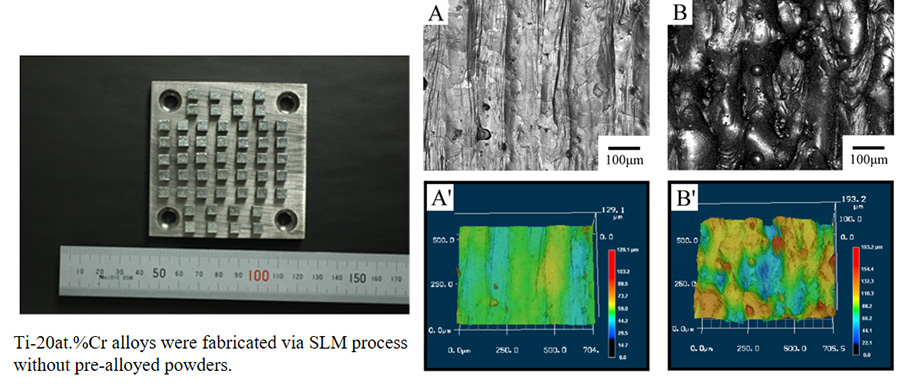

In this study, we success the fabrication of dense component of Ti-20at.%X (X = Cr and Nb) alloys by Selected laser melting (SLM) process, from a mixture of powders element powders. The volume rasio of pore and non-molten particles is dependent of the energy density. The difficulty of fabrication of Ti-X alloy component is dependent of melting temperature of X element. Thus, Ti-20at.%Cr alloys, which has the lowest melting temperature of X is easier to manufacture of dense component. The Ti-20at.%Cr alloys and Ti-20at.%Nb comprise β-Ti single-phase components without any non-molten particles and macroscopic defects. In addition, the {001}⟨100⟩ crystallographic texture of these Ti-Cr and Ti-Nb alloys can be controlled effectively by optimizing the SLM parameters. This means that the SLM is key techmelogy of controlling of Young’s modulus and shape at the same time because Young’s modulus of be-ta phase in Ti alloys is strongly related to the crystal orientation.

We success the fabrication of dense component of Ti-20at.%X (X = Cr and Nb) alloys by Selected laser melting (SLM) process, from a mixture of powders element powders.