Metallurgical Abstracts on Light Metals and Alloys vol.54

Peculiar microstructural evolution and tensile properties of β-containing γ-TiAl alloys fabricated by electron beam melting

Ken Cho*, Hajime Kawabata*, Tatsuhiro Hayashi*, Hiroyuki Y. Yasuda*, Hirotoyo Nakashima**, Masao Takeyama** and Takayoshi Nakano*

*Graduate School of Engineering, Osaka University

**School of Materials and chemical Technology, Tokyo Institute of Technology

[Published in Additive Manufacturing, Vol. 46 (2021), 102091]

https://doi.org/10.1016/j.addma.2021.102091

E-mail: k_cho[at]mat.eng.osaka-u.ac.jp

Key Words:Additive manufacturing, Titanium aluminide, Microstructure, Tensile properties

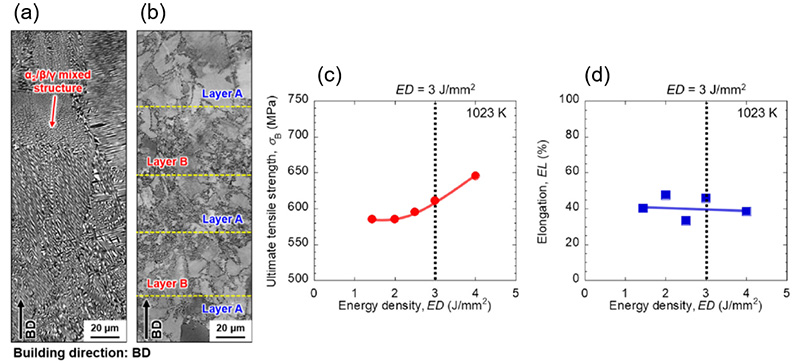

The microstructure and mechanical properties of β-containing Ti-44Al-4Cr alloy rods manufactured by electron beam melting process were examined focusing on input energy density determined by the processing parameters. We found for the first time that two types of fine microstructures have been obtained in the alloys by varying the energy density during the fabrication process. A uniform α2/β/γ mixed structure was formed at high energy density conditions. On the other hand, a peculiar layered microstructure perpendicular to the building direction consisting of a ultrafine α2/γ lamellar grain layer and a α2/β/γ mixed structure layer was obtained in the rods built at lower energy density conditions. This difference in the microstructures originates from the difference in the solidification microstructure and the temperature distribution from the melt pool, which are dependent on the energy density. Moreover, it was also found that the strength of the alloys is closely related to the volume fractions of the β phase and the ultrafine α2/γ lamellar grains which originates from the massive α grains formed by rapid cooling. The alloys with high volume fractions of these peculiar microstructures exhibit higher strength than the conventional β-containing γ-TiAl at 1023 K.

Microstructure of the rods fabricated at high (a) and low (b) input energy density and variations in the ultimate tensile strength (c) and the elongation (d) at 1023 K of the rods as a function of input energy density.