Metallurgical Abstracts on Light Metals and Alloys vol.54

Relationship between Microstructure and Fatigue Properties of Forged Ti-5Al-2Sn-2Zr-4Mo-4Cr for Aircraft Applications

Saki Tanaka*, Toshikazu Akahori**, Mitsuo Niinomi** and Masaaki Nakai***

*Graduate School of Science and Technology, Meijo University

**Faculty of Science and Technology, Meijo University

***Faculty of Science and Technology, Kindai University

[Published in Materials Transactions, Vol. 61 (2020), pp. 2017–2024]

https://doi.org/10.2320/matertrans.MT-M2020184

E-mail: akahori[at]meijo-u.ac.jp

Key Words:titanium alloy, solution treatment and aging, microstructure, fatigue strength

The fatigue properties including tensile properties and microstructures of near β-type Ti-5Al-2Sn-2Zr-4Cr-4Mo (Ti-17) samples fabricated by hot-forging at various temperatures, followed by high- and low-temperature solution treatment (ST), and same aging treatment were investigated to define a quantitative relationship between the fatigue properties and the microstructures.

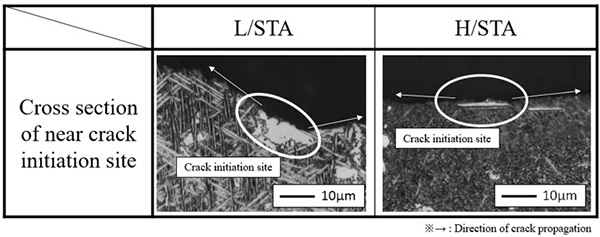

The microstructures of all forged Ti-17 samples exhibit elongated prior α-grains composed of two microstructural feature regions: acicular α and fine equiaxed α-phase regions. The volume fraction of the acicular α-region decreases with increasing ST temperature. The Vickers hardness, 0.2% proof stress and tensile strength increases with increasing ST temperature. However, the elongation and reduction of area exhibit a reverse trend. The Ti-17 samples forged at 1173 K followed by solution treatment at 1073 K and aging treatment exhibits the highest fatigue limit of around 975 MPa. The fatigue strength of the forged Ti-17 samples is strongly related to the microstructural factor such as the volume fraction of the equiaxed α-phase region, which is one of the crack initiation sites in the forged Ti-17 samples subjected to low temperature ST and aging, and the strength difference between the acicular α-phase and the fine (α+β)-phase, which leads to the crack initiation in the forged Ti-17 sample subjected to high temperature ST and aging.

Cross section of near crack initiation site hot-forged Ti-17 subjected to solution treatments at low and high temperatures (L/STA and H/STA, respectively).