Metallurgical Abstracts on Light Metals and Alloys vol.54

Microstructural Characterization and Wear Behavior of Sintered Compacts Fabricated from Plasma-nitrided Commercially Pure Titanium Powder

Shoichi Kikuchi*, Shiori Suzuki** and Hiroyuki Akebono***

*Faculty of Engineering, Shizuoka University

**Graduate School of Integrated Science and Technology, Shizuoka University

***Graduate School of Engineering, Hiroshima University

[Published in Materials Transactions, Vol. 61, No. 12, (2020), pp. 2284–2291]

https://doi.org/10.2320/matertrans.Z-M2020854

E-mail: kikuchi.shoichi[at]shizuoka.ac.jp

Key Words:Plasma nitriding, Commercially pure titanium, Powder metallurgy

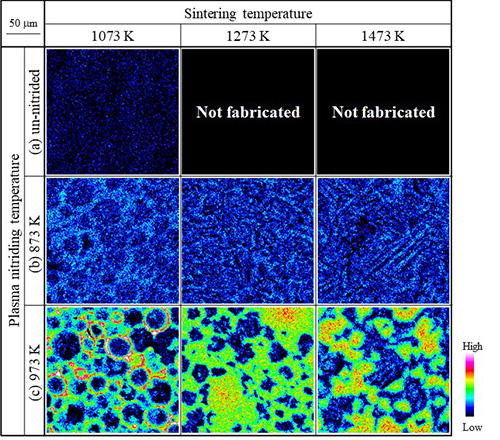

The microstructure of commercially pure (CP) titanium having a bimodal nitrogen diffusion phase for biomedical applications, which was fabricated by sintering plasma-nitrided powders, was characterized, and its effect on the wear behaviors was examined. The maximum nitrogen concentration and hardness of CP titanium having a bimodal nitrogen diffusion phase depended on the powder plasma nitriding and sintering temperatures. The grain size of CP titanium made by sintering plasma-nitrided powders is smaller than that of the un-nitrided one. As results of ball-on-disk dry friction tests, CP titanium fabricated from powder plasma-nitrided at 873K had lower wear resistance than compacts manufactured by sintering as-received CP titanium powder. In contrast, CP titanium fabricated from powder plasma-nitrided at 973K having a continuous connected network nitrogen diffusion phase had high wear resistance due to the high hardness and differences in the wear mechanism. The wear resistance of CP titanium is dependent on the powder plasma nitriding and sintering temperatures.

Nitrogen analyses by EPMA suggest that a profile of a nitrogen diffusion phase depends on both the plasma nitriding and sintering temperatures.