Metallurgical Abstracts on Light Metals and Alloys vol.54

Effect of Lamellar Spacing on Creep Strength of α-Mg/C14–Mg2Ca Eutectic Alloy

Koji Oishi*, Satoshi Araki* and Yoshihiro Terada*

*Department of Materials Science and Engineering, Tokyo Institute of Technology

[Published in Journal of the Japan Institute of Metals and Materials, Vol. 85 (2021), pp. 223–228]

https://www.jstage.jst.go.jp/article/jinstmet/85/6/85_J2021005/_article/-char/en

E-mail: terada.y.ab[at]m.titech.ac.jp

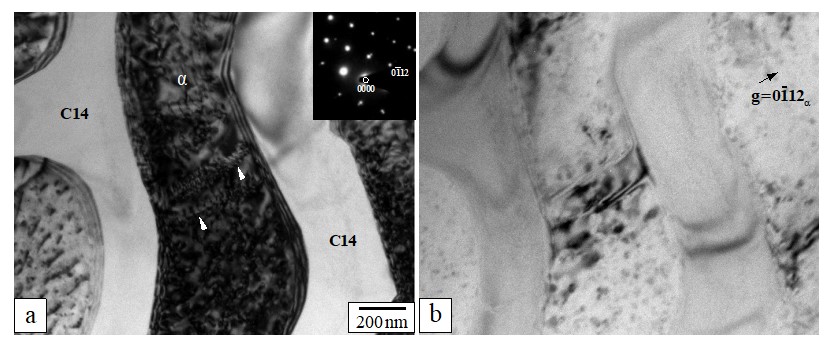

Keywords: magnesium–calcium alloy, lamellar spacing, interface, creep, dislocation

In tensile tests, α-Mg/C14–Mg2Ca eutectic alloy with a lamellar structure is plastically deformed above 473 K but ruptures before yielding at temperatures below 423 K. This study investigates the effect of the α/C14 interface on the creep strength of α-Mg/C14–Mg2Ca eutectic alloy at 473 K under 40 MPa stress. The creep curves of the alloy exhibited three stages: a normal transient creep stage, minimum creep-rate stage, and accelerating stage. The minimum creep rate was proportional to the lamellar spacing, indicating that the α/C14 lamellar interface plays a creep-strengthening role. In high-resolution transmission electron microscope observations of the specimens after the creep test, a dislocations appeared within the α-Mg lamellae and were randomly distributed on the α/C14 interface. It was deduced that the α/C14 interface presents a barrier to dislocation glide and does not annihilate and/or rearrange its dislocation caused by the creep test.

Figure HRTEM image, taken with B = [01-11]α, of the as-cast α-Mg/C14–Mg2Ca eutectic alloy creep- ruptured at 473 K under a stress of 40 MPa under (a) multiple and (b) two-beam diffraction conditions. The dislocation alignment is indicated by white arrowheads in (a).