Metallurgical Abstracts on Light Metals and Alloys vol.54

Amorphization at the welded boundary between 5052 aluminum alloy and zirconium by friction stir diffusion bonding

Tokujiro Yamamoto*, Takashi Kodama**, Yoshimasa Takayama* and Hideo Watanabe*

*Department of Mechanical and Intelligent Engineering, Utsunomiya University

**Graduate Student, School of Engineering, Utsunomiya University

[Published in Journal of the Japan Institute of Ligtht Metals, Vol. 70 (2020), pp. 523–529]

https://www.jstage.jst.go.jp/article/jilm/70/11/70_701104/_article/-char/en

E-mail: toku[at]cc.utsunomiya-u.ac.jp

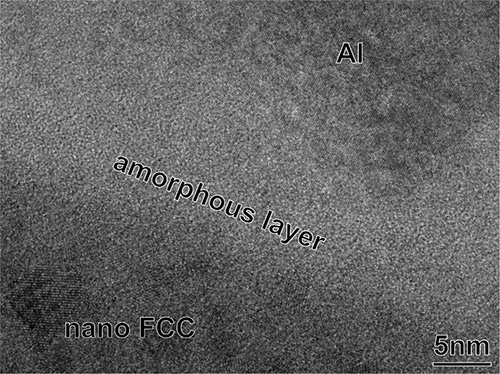

Key Words:dissimilar welding, local melting, rapidly quenching, amorphization, nanocrystallization

Microstructure at the boundary between 5052Al and zirconium foils subjected to friction stir diffusion bonding. 5052Al and zirconium foils were welded by travelling of a rotating tool with microindention only into the 5052Al foil. The welding strength of the specimens was higher than the fracture strength of the 5052Al foil. An amorphous layer with a thickness of 2 to 100 nm was found at the welded boundary by edge-on transmission electron microscopy (TEM) observation. An amorphous phase at a welded boundary has been also reported for other dissimilar metal welding, e.g. aluminum and iron alloys, which exhibits high welding strength. No intermetallic compounds were found at the boundary. The welding strength was sufficiently higher than the fracture strength of the 5052Al foils. Local melting followed by rapid quenching at the dissimilar welding boundary amorphizes or nanocrystallizes the boundary between the Al and the transition metals, which are a pair of metal elements generating a large amount of heat of mixing, and the welding strength tends to be high.

High resolution electron microscopy image of the amorphous layer found at the welded boundary of 5052Al and zirconium.