Metallurgical Abstracts on Light Metals and Alloys vol.54

Investigation of Hot Workability and Microstructure Evolution of VGCNFs-Reinforced Aluminum Matrix Composites

Ying Guo*,**, Xin-Gang Liu*, Xin-Sheng Shi*, Jun-Jie Zou*, Zhe-Feng Xu*, Yu-Jiao Ke* and Gen Sasaki**

*College of Mechanical Engineering, Yanshan University

**Department of Mechanical Materials Engineering, Hiroshima University

[Published in Metallurgical and Materials Transactions A, Vol. 51A (2020), pp. 4100–4112]

https://doi.org/10.1007/s11661-020-05834-w

E-mail: gen[at]hiroshima-u.ac.jp

Key Words:Composites, Carbon nano-fiber, Isothermal compression test, Dynamic recrystallization

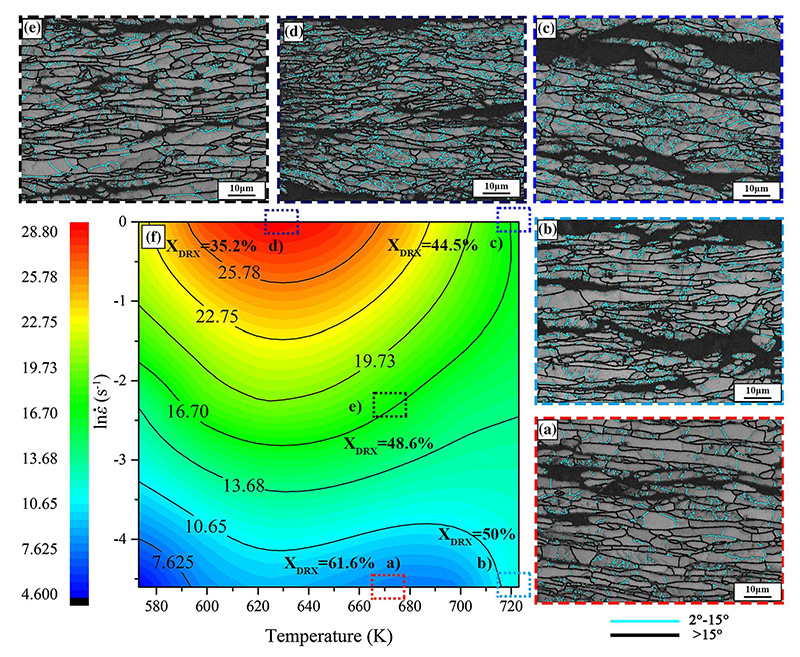

Isothermal compression experiments of vapor-grown carbon nanofiber (VGCNF)-reinforced aluminum matrix (VGCNF/Al) composites and pure aluminum (Al) were conducted at deformation temperatures from 573 K to 723 K and strain rates from 0.01 to 1 s-1. It was found that the VGCNF/Al composites and pure Al had depressed dynamic recrystallization percent in the high-power dissipation efficiency regions. Upon comparing the processing maps for different strains, it was found that the high-power dissipation efficiency regions of the VGCNF/Al composites and pure Al moved from the low strain rate region to the high strain rate region. The kernel average misorientation images showed that there were lots of low-angle grain boundaries in the high strain rate region. The low-angle grain boundaries did not have enough time to transform into high-angle grain boundaries, resulting in a depressed percentage of dynamic recrystallization. The addition of VGCNFs led to an increased low-angle grain boundary density. As a result, the phenomenon of high-power dissipation regions in the high strain rate regions correspond to the low percentage of dynamic recrystallization was more obvious.

Microstructure of VGCNF/Al composites in different power dissipation efficiency regions: (a) 673 K-0.01s-1, (b) 723 K-0.01s-1, (c) 723 K-1s-1, (d) 623 K-1s-1, (e) 573 K-0.1s-1 and (f) the processing map when the strain was 0.35.