Metallurgical Abstracts on Light Metals and Alloys vol.54

Microstructure and thermal properties of nickel-coated carbon fibers/aluminum composites

Li-Fu Yi, Takashi Yamamoto, Tetsuhiko Onda and Zhong-Chun Chen

Department of Mechanical and Aerospace Engineering, Graduate School of Engineering, Tottori University

[Published in Journal of Composite Materials, Vol. 54 (2020), pp. 2539–2548]

https://doi.org/10.1177/0021998319899154

E-mail address: chen[at]mech.tottori-u.ac.jp

Keywords: Electroless nickel coating, Carbon fibers/Al composite, Thermal conductivity, Coefficient of thermal expansion

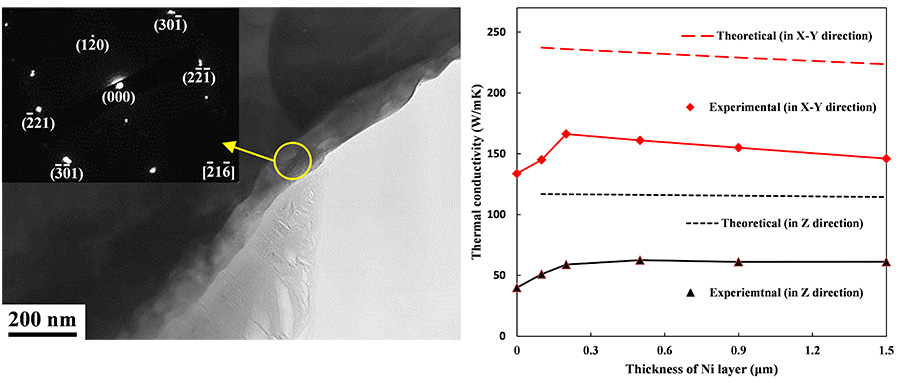

Abstract: Electroless nickel-coated carbon fibers/aluminum composites were prepared by spark plasma sintering, and the effect of nickel coating on microstructure and thermal properties of the composites has been investigated. Nickel coating on carbon fibers resulted in more homogeneous distributions of carbon fibers in aluminum matrix, higher relative density of carbon fibers/aluminum composites, and stronger interfacial bonding between carbon fibers and aluminum. Microstructural observations exhibited that the majority of carbon fibers were randomly distributed on the sections (X-Y direction) perpendicular to spark plasma sintering pressing direction (Z direction), thus leading to an anisotropic behavior in thermal conductivity of the composites. The thermal conductivity values in the X-Y direction of the carbon fibers/aluminum composites were much higher than those in the Z direction. As a result, the nickel-coated carbon fibers/aluminum composites with a nickel-coating thickness of ~0.2µm showed higher thermal conductivity and lower coefficient of thermal expansion values in comparison with those of the uncoated carbon fibers/aluminum samples.

A uniform metallurgical interfacial bonding was formed in the 1.5min coated CFs/Al sample. The TC values of the coated samples were higher than that of the uncoated sample.