Metallurgical Abstracts on Light Metals and Alloys vol.54

Stability of crystallographic texture in laser powder bed fusion:

Understanding the competition of crystal growth using a single crystalline seed

Takuya Ishimoto*,**, Koji Hagihara*,**, Kenta Hisamoto* and Takayoshi Nakano*,**

*Division of Materials and Manufacturing Science, Graduate School of Engineering, Osaka University,

2-1, Yamada-oka, Suita, Osaka 565-0871, Japan

**Anisotropic Design & Additive Manufacturing Research Center, Osaka University, 2-1, Yamada-oka, Suita, Osaka 565-0871, Japan

[Published in Additive Manufacturing, Vol. 43 (2021), 102004]

https://doi.org/10.1016/j.addma.2021.102004

E-mail: nakano[at]mat.eng.osaka-u.ac.jp

Key Words:Laser powder bed fusion, Crystallographic texture, Stability, Crystal growth, Single crystal

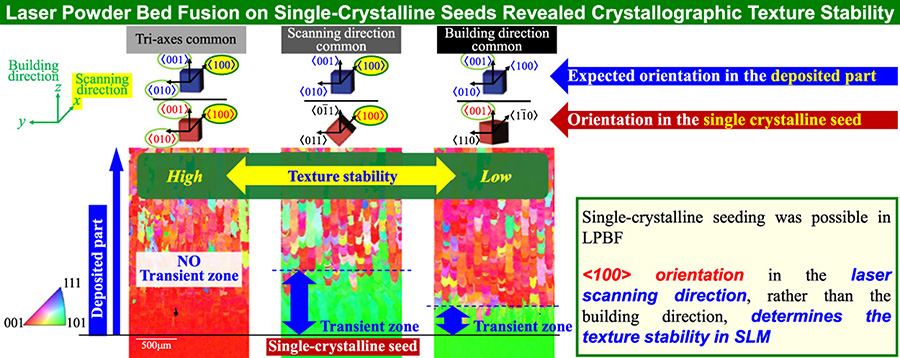

In metal additive manufacturing, control of crystallographic orientation is a promising method for tailoring the functions of metallic parts. However, despite its importance in the fabrication of texture-controlled functional parts, the stability of the crystallographic texture is not yet fully discussed. In this study, the stability of crystallographic texture under laser powder bed fusion was investigated. Two methodologies were employed. One is that a laser scanning strategy was alternately changed for a specific number of layers. The other is a “seeding” experiment in which single-crystalline substrates with controlled crystallographic orientations in the building direction (z-) and the xy-plane (perpendicular to the building direction) were used as the starting substrate. The transient zone width, where the crystallographic orientation was inherited from the layer beneath, was analyzed to evaluate the texture stability. The crystallographic direction of the seed within the xy-plane, rather than the building direction, determined the transient zone width, i.e., the texture stability. In particular, the texture in the newly deposited region was stable when the laser scanning direction matched the <100> orientation in the underneath layer, otherwise the crystal orientation switched rapidly, such that the <100> orientation was parallel to the scanning direction. Interestingly, the crystallographic orientation along the building direction in the underneath layer hardly affected the stability of the texture. Therefore, for the first time, we have clarified that the <100> orientation in the scanning direction, rather than the building direction, was preferentially stabilized, whereas the orientation in the other directions secondary stabilized.

Schematic illustration of impression pattern.