Metallurgical Abstracts on Light Metals and Alloys vol.54

Transition of dominant deformation mode in bulk polycrystalline pure Mg by ultra-grain refinement down to sub-micrometer

Ruixiao Zheng1,2, Jun-Ping Du3,4, Si Gao2, Hidetoshi Somekawa5, Shigenobu Ogata4,3 and Nobuhiro Tsuji2,3

1School of Materials Science and Engineering, Beihang University, Beijing 100191, China

2Department of Materials Science and Engineering, Kyoto University, Yoshida Honmachi, Sakyo-ku, Kyoto 606-8501, Japan

3Elements Strategy Initiative for Structural Materials (ESISM), Kyoto University, Yoshida Honmachi, Sakyo-ku, Kyoto 606-8501, Japan

4Department of Mechanical Science and Bioengineering, Osaka University, Osaka 560-8531, Japan

5National Institute for Materials Science, 1-2-1 Sengen, Tsukuba 305-0047, Japan

[Published in Acta Materialia, Vol. 198 (2020), pp. 35–46]

https://doi.org/10.1016/j.actamat.2020.07.055

E-mail: nobuhiro-tsuji[at]mtl.kyoto-u.ac.jp

Key Words:Magnesium, Strength and ductility; Deformation mode; Hall-Petch relationship; Grain size

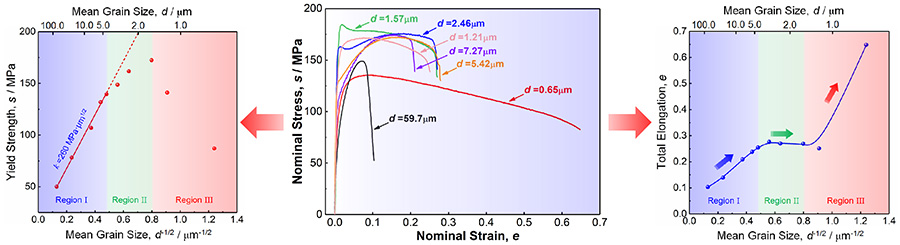

Magnesium (Mg) and its alloys usually show relatively low strength and poor ductility at room temperature due to their anisotropic hexagonal close-packed (HCP) crystal structure that provides a limited number of independent slip systems. Here we report that unique combinations of strength and ductility can be realized in bulk polycrystalline pure Mg by tuning the predominant deformation mode. We succeeded in obtaining the fully recrystallized specimens of pure Mg having a wide range of average grain sizes, of which minimum grain size was 650 nm, and clarified mechanical properties and deformation mechanisms at room temperature systematically as a function of the grain size. Deformation twinning and basal slip governed plastic deformation in the conventional coarse-grained region, but twinning was suppressed when the grain size was refined down to several micro-meters. Eventually, grain boundary mediated plasticity, i.e., grain boundary sliding became dominant in the ultrafine-grained (UFG) specimen having a mean grain size smaller than 1 μm. The transition of the deformation modes led to a significant increase of tensile elongation and breakdown of Hall-Petch relationship. It was quantitatively confirmed by detailed microstructural observation and theoretical calculation that the change in strength and ductility arose from the distinct grain size dependence of the critical shear stress for activating different deformation modes.

Effect of grain size on the yield strength and total elongation in the pure Mg was divided into three different regions corresponding to the change of the major deformation mode.