Metallurgical Abstracts on Light Metals and Alloys vol.54

Multi-Directional Forging and Warm Extrusion of AZ80Mg Alloys

Hiromi Miura*, Keiichiro Minami*, Masakazu Kobayashi* and Chihiro Watanabe**

*Department of Mechanical Engineering, Toyohashi University of Technology

**Institue of Science and Engineering, Kanazawa University

[Published in Mater. Trans., Vol. 62(2021), pp. 610–619]

https://doi.org/10.2320/matertrans.MT-M2020360

E-mail: Miura[at]me.tut.ac.jp

Key Words:Ultrafine grain, Dynamic recrystallization, Multi-directional forging, Magnesium, Extrusion

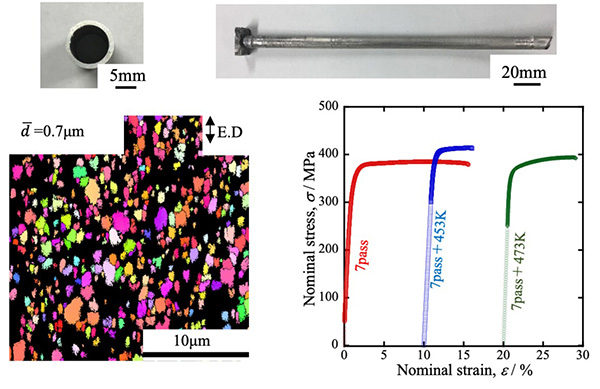

A commercial hot-extruded AZ80Mg alloy was multi-directionally forged (MDFed) to a cumulative strain of ΣΔε = 5.6 at maximum under decreasing temperature conditions from 623 K down to 433 K at an initial strain rate of 3.0 × 10-3 s-1. In addition to the above MDFing method, a simplified MDFing method, i.e., MDFing under two-step decreasing temperature conditions, was proposed and applied. These MDFing led to homogeneous grain refinements to have average grain sizes down to 0.6 µm. The MDFed Mg alloys were further extruded to form plates and tubes at temperatures between 453 K and 523 K at various initial strain rates from 3.0 × 10-4 s-1 to 1.0 × 10-2 s-1. Extrusions of the MDFed AZ80Mg alloys were successfully carried out even at such relatively low temperatures. Under some conditions, the strain-rate sensitivity of the flow stress exceeded 0.3, which suggested occurrence of superplastic deformation. By the above warm extrusion employing superplasticity accompanied by work hardening, high-strength AZ80Mg alloy tubes with tensile strength over 400 MPa could be successfully fabricated.

High-strength AZ80Mg alloy tube could be successfully fabricated by combined processes of multi-directional forging and warm-temperature extrusion employing superplasticity.