Metallurgical Abstracts on Light Metals and Alloys vol.54

Optimization of the Surface Structure of the Si Substrate for Si-Al Bonding Using Simulation by the Phase Field Method

Kyohei Iwata*, Ryusuke Yuchi*, Yasushi Sasajima*, Jin Onuki*

*Department of Materials Science and Engineering, Graduate School of Science and Engineering, Ibaraki University

[Published in Journal of Electronic Materials Vol. 50 (2021), pp. 4770–4780]

https://doi.org/10.1007/s11664-021-08998-2

E-mail: yasushi.sasajima.mat[at]vc.ibaraki.ac.jp

Key Words: Si-Al bonding, regrowth layer, interface shape control, phase field method,

Gibbs-Thomson effect

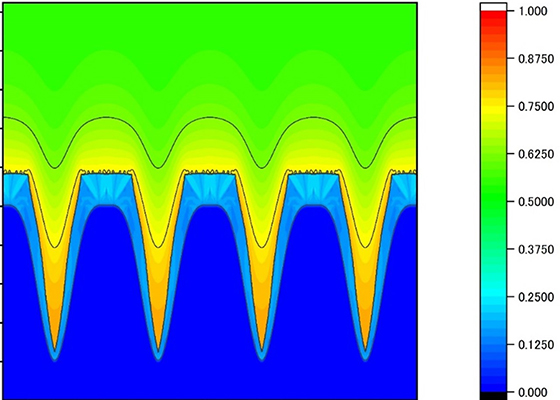

We investigated the optimal surface structure of an n-type Si substrate for Si-Al bonding (which prevents high energy barrier formation) using simulation by the phase field method. The surface structure of the substrate contained a groove to suppress regrowth layer formation at the bottom of the groove. We determined the appropriate width and depth of the groove to suppress the regrowth layer effectively. The features of the regrowth layer suppression mechanism were clarified as the following: narrowing the groove caused the Al concentration to increase inside the groove and, in turn, decreased the degree of supercooling of the Si-Al liquid. However, when the groove was too narrow, the radius of curvature at the bottom of the groove decreased, and the equilibrium melting point of the Si-Al liquid rose due to the Gibbs-Thomson effect. On the other hand, the narrow groove increased the Al concentration, leading to decrease of the equilibrium melting point of the Si-Al liquid. This implies that there is always an optimum value for the width and the depth of the groove by which the regrowth layer is effectively suppressed through forming the groove in the Si surface for the Si-Al bonding process. Any groove morphology with the growth ratio (the ratio of the regrowth layer at the bottom to that at the top of the groove) less than 0.3 is appropriate to achieve good ohmic contact; however, it is considered that the groove with periodic length of 9.4 μm and aspect ratio around 0.2 is the best because of the ease of manufacturing.

Concentration distribution of Al after 1.4 ms for A = 1.68 μm and λ = 4.7 μm.