Metallurgical Abstracts on Light Metals and Alloys vol.55

Enhanced mechanical properties in an Al-Mg-Cu alloy processed by the combination of cyclic deformation and aging heat treatment

Xuanliang Chen*, Minho O* and Equo Kobayashi*

*Department of Materials Science and Engineering, Tokyo Institute of Technology, 2-12-1-S8-18, Ookayama, Meguro-ku, Tokyo 152-8552, Japan

[Published in Journal of Alloys and Compounds, Vol. 911 (2022), pp. 165070]

https://doi.org/10.1016/j.jallcom.2022.165070

E-mail: equo[at]mtl.titech.ac.jp

Key Words: Al alloys, Cyclic deformation, Aging, Mechanical properties, Precipitation

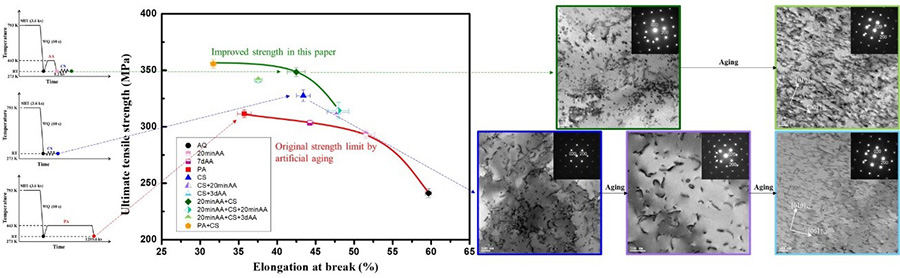

Aging is a traditional strengthening method used for heat-treatable Al alloys. Cyclic strengthening has recently received widespread attention as a novel method for alloy strengthening. This study applied cyclic deformation to introduce dislocations and promote cluster formation in an Al-Mg-Cu alloy. Cyclically-strengthened (CS) samples have higher strength and ductility than peak-aged samples. The aging behaviors of the CS samples and the effect of pre-aging (artificial aging prior to cyclic deformation) on cyclic strengthening were also studied. Recovery and precipitation promotion were found during the aging of the CS samples regardless of pre-aging for 20 min. The pre-aged CS samples show higher strength than the CS samples without pre-aging. Interestingly, after subsequent aging, the mechanical properties of the CS samples with and without 20 min of pre-aging became the same. In summary, aging and cyclic deformation methods were combined to maximize the effects of precipitation strengthening and work-hardening. The strength limit obtained by individual aging or cyclic deformation methods was successfully overcome. This study provides new insights into alloy strengthening.

Cyclic deformation leads to a significant strengthening effect on Al-Mg-Cu alloys due to clusters and dislocations. The mechanical properties are further enhanced by the combination of cyclic deformation and aging.