Metallurgical Abstracts on Light Metals and Alloys vol.55

Enhanced Mechanical Properties in 6082 Aluminum Alloy Processed by Cyclic Deformation

Xuanliang Chen*, Eva Anne Mørtsell**, Jonas Kristoffer Sunde***, Minho O*, Calin D. Marioara****, Randi Holmestad*** and Equo Kobayashi*

*Department of Materials Science and Engineering, Tokyo Institute of Technology, 2-12-1-S8-18, Ookayama, Meguro-ku, Tokyo, 152-8552, Japan

**Research and Technology Development, Hydro Aluminium, Romsdalsvegen 1, N-6601 Sunndalsøra, Norway

***Department of Physics, Norwegian University of Science and Technology, Høgskoleringen 5, N-7491, Trondheim, Norway

****Materials and Nanotechnology, SINTEF Industry, Høgskoleringen 5, N-7465, Trondheim, Norway

[Published in Metals, Vol. 11 (2021), pp. 1735]

https://doi.org/10.3390/met11111735

E-mail: equo[at]mtl.titech.ac.jp

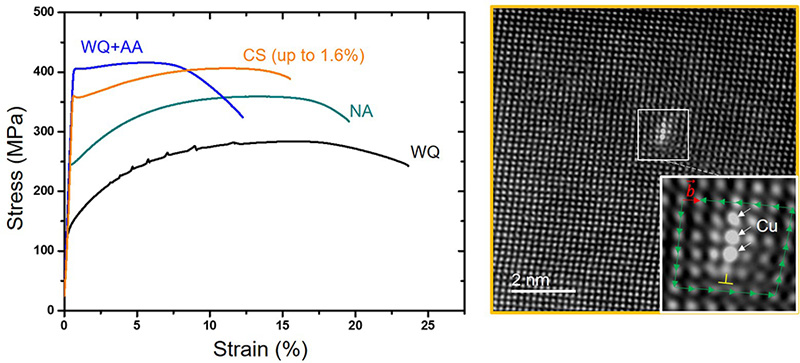

Key Words: Al-Mg-Si alloy, cyclic deformation, precipitation, mechanical properties, electron microscopy

Aging heat treatment is the most commonly used strengthening method for Al-Mg-Si alloys since high-density precipitates will be formed to hinder the movement of dislocations. In the current work, room temperature cyclic deformation was attempted to strengthen the alloy. We compared tensile test results of aged samples and cyclically deformed samples. It was found that cyclically deformed samples can achieve similar strength and approximately twice the uniform elongation as the peak aged samples. The high density of dislocations and nanoclusters observed in the cyclically deformed samples is thought to be the main reason for strengthening. Different cyclic deformation conditions have been tried and their effects were discussed.

The CS sample has excellent mechanical properties. The direct evidence of Cu aggregation on an edge dislocation was observed.