Metallurgical Abstracts on Light Metals and Alloys vol.55

Effects of multi-directional forging on texture and hardness in A5052 aluminum alloy

Keizo Kashihara* and Daiki Ogura**

*Department of Intelligent Mechanical Engineering, Wakayama National College of Technology

**Student, Department of Intelligent Mechanical Engineering, Wakayama National College of Technology

[Published in Journal of The Japan Institute of Light Metals, Vol. 72, No. 7 (2022), pp. 420–426]

https://www.jstage.jst.go.jp/article/jilm/72/7/72_720703/_article/-char/en

E-mail: kashihara[at]wakayama-nct.ac.jp

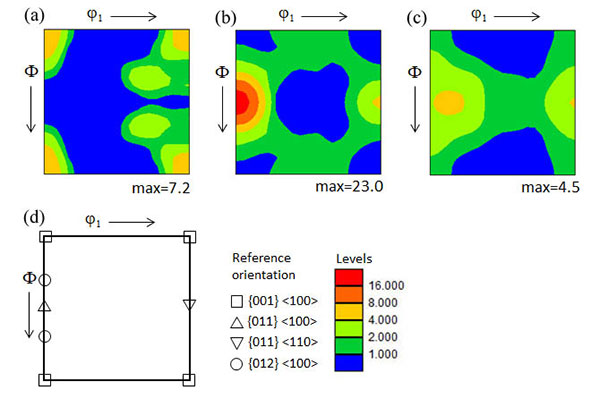

Key Words: aluminum alloy, multi-directional forging, unidirectional forging, texture, hardness

The effect of multi-directional forging on the development of texture and increase of hardness was investigated for a commercial A5052 aluminum alloy, which had an initial texture with a major orientation of {001} <100>. Two specimens were prepared: one was obtained via multi-directional forging (MDF) performed four times at a true strain of 0.18 for each forging, while the other was prepared via unidirectional forging (UDF) performed one time at a true strain of 0.72. The specimens obtained via MDF and UDF at the same true strain of 0.72 exhibited the same tendencies in terms of hardness, grain diameter, and Kernel average misorientation (KAM) value. The specimen after undergoing MDF four times had a deformation texture with major and minor orientations of {011} <100> and {011} <110>, respectively. The formation of {011} <100> can be explained using the Sachs model, in which slip systems undergoing maximum resolved shear stress are activated during MDF. Furthermore, it was concluded that the formation of {011} <110> after the specimen underwent MDF four times was caused by the appearance of {001} <110> after performing the MDF of the specimen for three times.

Orientation distribution function (ODF) at the section of φ2=0° for (a) Specimen before forging, (b) Specimen forged by four times at a true strain of 0.18, (c) Specimen forged by four times at a true strain of 0.18, (d) main reference orientations.