Metallurgical Abstracts on Light Metals and Alloys vol.55

Influence of ultrasound irradiation on transient solidification characteristics in DC casting process: Numerical simulation and experimental verification

Takuya Yamamoto* and Sergey Komarov*

*Department of Metallurgy, Graduate School of Engineering, Tohoku University

[Published in Journal of Materials Processing Technology, Vol. 294 (2021), pp. 117116]

https://doi.org/10.1016/j.jmatprotec.2021.117116

E-mail: t-yamamoto[at]tohoku.ac.jp

Key Words: DC casting, Acoustic streaming, Aluminum melt, Ultrasonic irradiation

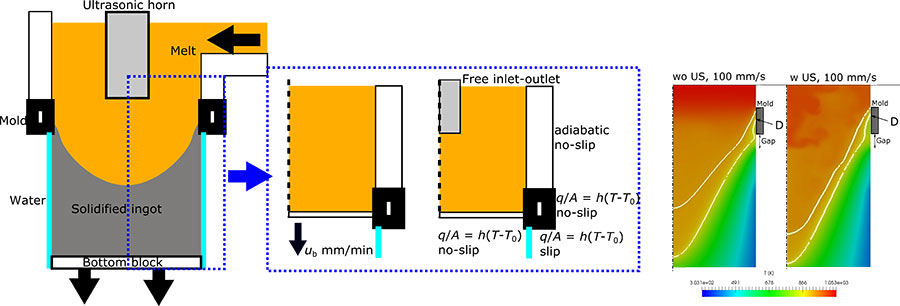

It is well known that solidification of molten metals occurs under the influence of transient unsteady phenomena, which are difficult to control in actual casting operation. Examples include buoyancy flows, natural heat con- vection, repeated remelting and solidification in mushy zone and solid shell at the mold interface. This paper presents the results suggesting that ultrasound waves, irradiated into the hot-top mold offers an attractive way to control the transient phenomena in DC casting of aluminum alloy billets. A novel mathematical model was developed to simulate the DC casting with considering transient melt flow, heat transfer, ultrasound propagation, acoustic streaming and solidification. It was found that ultrasound irradiation alters the solidification behavior of melt and sump evolution especially in the earlier stage of casting, however as the billet length increases, the sump profile becomes almost the same for both the ultrasonic and conventional castings. In this condition, the casting speed becomes the key parameter influencing the sump evolution and mushy zone volume. The results reveal that ultrasound-driven acoustic streaming and turbulent oscillations result in a suppression of buoyancy flow in the sump and lead to an increase of frequency of the melt temperature oscillations at the solidification interface. One of the useful results of these phenomena can be a more frequent repetition of remelting/solidi- fication cycle and improvement of the billet quality, particularly the billet surface morphology. The effect of ultrasound irradiation on the billet morphology was verified experimentally using a pilot DC caster.

Schematic drawings of computational domain and simulated temperature distribution during conventional and ultrasonic DC casting process.