Metallurgical Abstracts on Light Metals and Alloys vol.55

Preparation of Ideally Ordered Anodic Porous Alumina by Prepatterning Process Using a Flexible Mold

Takashi Yanagishita*, Kenya Kato*, Naoto Shirano* and Hideki Masuda*

*Department of Applied Chemistry, Tokyo Metropolitan University

[Published in ECS J. of Solid State Sci. and Technol., Vol. 11 (2022), p. 013001]

https://doi.org/10.1149/2162-8777/ac479b

E-mail: yanagish[at]tmu.ac.jp

Key Words: Ideally ordered anodic porous alumina, stamp, flexible mold

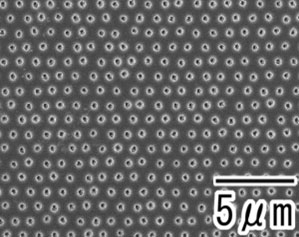

Ideally ordered anodic porous alumina with controlled interpore distances was formed by the formation of a resist mask using a flexible mold and subsequent anodization. Prior to forming the resist pattern on the surface of an Al substrate, Al was pre-anodized to prepare the fine porous structure, which acts as a resist adhesive layer. After the formation of the resist mask using a flexible mold, an arranged array of a cavity with exposed Al on the bottom was formed by selective dissolution of the oxide layer at resist openings. The subsequent anodization of the sample with the cavity array generated ideally ordered anodic porous alumina because alumina holes were formed at the bottom of cavities during anodization. This process allows the preparation of ideally ordered anodic porous alumina even on the curved Al surface due to the flexibility of the mold. In addition, this process can also be applied to the preparation of an ideally ordered anodic porous alumina with a large sample area because Al substrate can be patterned without high pressure.

Ideally ordered anodic porous alumina with an interhole distance of 1 µm prepared by the present process.